radioman

Super Member

My father had a small massey ferguson lawn dump cart that is made with thick metal sheet for over 30 years. I have tried to find another one just like it and no one makes it like it anymore. I bought a crappy lawn dump cart from tractor supply with nice tires but the sheet metal is like 1/16 thick! It doesnt hold up well and I had to tack weld it back together in many places. So it time to make my own that would be easy to service and keep for many years to come.

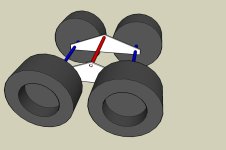

I need your help to see if my dream can come true or not. I am thinking of making a towbehind trailer for my BX with daul axels that is onyl 4 ft by 6 ft or so long. I am hoping to take apart two OLD junk lawn tractors for the rear tires and maybe the axels.

My questions are: can I use old bed frames for the frame of the trailer or is it too soft and thin? Has anyone taken old lawn cheapo tractor transaxels apart and salvage the axels and use rear tires? What should I think about when building a small trailer for my BX ? I am hoping to use next to free parts for building this trailer, but right now its a pipe dream until I realize it can be feasible. I have a 110V welder, buncha of hand tools and a can do attitude.

I was thinking of using the rear large tires from lawn tractors for trailer tires to support more weight and be more stable for hauling firewood in winter mostly and dirt for summer projects. I proabably will make it a dump trailer and will do it manaully but I want to optimize it and make it hydralic ready as well for future when I get too old to lift. I might make it mostly out of osb or plywood and will replace it every 5-10 year due to dryrot unless someone can point me to 1/4 thick sheet metal.

I would appriecate ideas and suggestion so I can collect parts over the winter for a spring project.

I need your help to see if my dream can come true or not. I am thinking of making a towbehind trailer for my BX with daul axels that is onyl 4 ft by 6 ft or so long. I am hoping to take apart two OLD junk lawn tractors for the rear tires and maybe the axels.

My questions are: can I use old bed frames for the frame of the trailer or is it too soft and thin? Has anyone taken old lawn cheapo tractor transaxels apart and salvage the axels and use rear tires? What should I think about when building a small trailer for my BX ? I am hoping to use next to free parts for building this trailer, but right now its a pipe dream until I realize it can be feasible. I have a 110V welder, buncha of hand tools and a can do attitude.

I was thinking of using the rear large tires from lawn tractors for trailer tires to support more weight and be more stable for hauling firewood in winter mostly and dirt for summer projects. I proabably will make it a dump trailer and will do it manaully but I want to optimize it and make it hydralic ready as well for future when I get too old to lift. I might make it mostly out of osb or plywood and will replace it every 5-10 year due to dryrot unless someone can point me to 1/4 thick sheet metal.

I would appriecate ideas and suggestion so I can collect parts over the winter for a spring project.