OK rox, here is an outside the box suggestion.

I know you aren't allowed to process olives in your existing garage, but can you store them and heat them in the garage? We think so and probably will do this although prolly not 100% legal. Rain is our issue here, we need to keep the olives out of the rain.

If you can do that, the way I would set this up would be to put a warming station in the garage.

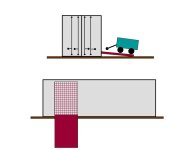

Then I would get a 20 foot container. You say the equipment can be installed in a 5.6 meter length, which is 18.67 feet. The equipment can all be installed inside the container. And I don't really think you want to do anything in that container other than process olives. From reading the literature on it, and looking at the drawings, it appears that this mill is pretty self contained. You dump olives in one end and pump olive oil, dirty process water, and depleted olive paste out at various locations. That is it, that is why I made the flow chart.

Set the mill in the container up close to your garage. It is going to be 50ft from the garage, that is why I went out and took site pics to post, to show the site. Get a some wagons which can be used to haul pre-weighed olive crates to the input end of the mill. We already have a wagon very similar to what you show jsut smaller, I think it holdds 4 crates 2 on the botttom and then stacked 2 on top. It has the tires that go over gravel. Dump the olives into the hopper and go back for more. I don't know what your olive oil carts look like, but you either need to get ones with wheels big enough to roll on your gravel, or put them on wagons with big wheels.

Here is the kind of wagon I am thinking of - Harbor Freight Tools - Quality Tools at the Lowest Prices I have exactly this one and it will easily carry hundreds of pounds of material over my gravel driveway. I have also seen ones with wire mesh sides, but don't have a link to them.

You will probably need more than one, but they are inexpensive. You can either pull them by hand, or use some kind of tractor or vehicle to tow them. If you can use your neighbors mini-excavator with forks that would be ideal. Instead of wagons, put the boxes and oil containers on pallets and fork them around.

You don't have to bring the wagons into the container. Dump the olives into the hopper by hand and pump or drain (depends on how the centrifuge works) the oil out into oil carts already on the wagons.

This eliminates dragging anything heavy over the floor and opens up the possibility of concrete, vinyl, or fiberglass over the floor. The press itself is still gonna be pretty heavy.

When you say that tile floors are acceptable do you mean ceramic tile or vinyl tile? Are vinyl floors like those used in kitchens (similar to rolls of linoleum) acceptable? I don't think we can have vinyl. See in my next post the attached file item # 6. Looks like the flooring has to be fireproof.

If you can put seamless vinyl from a roll on the floor that is vastly easier than concrete, as Jake says. But to have that material last any length of time you have to keep all the olive crate dragging, oil cart moving, etc out of the container.

There is a second reason to eliminate olive crates and oil carts from the part of the container with the machinery--they won't fit. The pinch point is the centrifuge. If you place it the way shown on the schematic, it is 1.94 meters wide and the inside of the container is only 2.33 meters. This means you can have 18.5 cm (7 1/4") of room on each side. You might think you can do better by turning the centrifuge sideways, but the 1.70 meter length there does not include the space for that nice big, fat olive paste hose that I see in the flow chart picture. That is an excellent term, pinch point. We will eliminate the tub that receives the oil off of the centrifuge that will give us a bit more space. But you are right we are going to have a pinch point which is why we will go with the 40 ft container. I want to have room on one side for crates on the intake side, think rain, and 60 liter drums of pressed oil on the output side. We need ingress and egress on both sides of the pinch point. This is going to be inconveinent but workable. It is not ideal but there is room in the container for the press. It'll fit. But a 20ft one Dave I think is just to small. We also need to add a floor scale as shown on the flow chart you need to weigh first the olives then the finished oi, 20 ft would be to small. Although I might sotre olives pre press in our existing garage I don't think customers are going to want their drums of oil in the garage, I'll need to keep it inside the container, just for estetiques. They will drop off olives one day and pick up olive oil the next day. The price differrence between the 20ft and 40ft was not that bad and we have the site space so unless you come up with another compelling idea I'm pretty sure it is going to be 40ft.

No matter how you slice it, access to the container will be from each end, and there will be a nearly complete blockade as far as moving or dragging anything past the centrifuge. This is a very good reason to make the container as short as possible.

How many operators does the mill require? I don't mean people loading olives, or removing oil and waste products, just people babysitting the machine itself. My sense is that you only need one person to start it up, watch it run and maybe make adjustments from time to time. And, once it is running that is only a part time job. If this is correct, I would design the operation so that this person was the only person who went into the container. The people feeding the machine and taking away product don't need to go in there. Mainly it will be one person but frequently 2 people.

Now, if you need ventilation anyway, just keep the original swinging doors on the container and open both ends wide for ventilation. The only reason to consider heating the container at all is if you have to go in there to repair the equipment. Especially since that is how all of the other mills do it. rox, you can buy a lot of snow bunny suits for the price of the heaters and electricity you will need to heat that container. Especially with both ends open. We do need lighting, we do need windows, it will be to dark without windows. Also the cargo door end will be facing north and we get very very strong northern winds called the Mistral. When we have wind, which is frequeently,

I'll want to open the East/West windows for ventilation.

The other thing to think about is that the picture on the MillFlowChart shows what I would call a skid-mounted olive oil press. Now, I know you aren't planning to buy this, but is something like that legal for use in France? The reason I ask is that I don't see the bowl shaped floor and channel running down the middle. You can see the regs in my next post. They are going to want the whole container floor to be sloped.

If the skid mounted unit is legal, you might want to consider the extra cost of the skid mount vs. the cost of a floor with channel. How wide is that metal platform?

I bet you it would be possible to slide that skid lengthwise into a container and never have to worry about the floor.

Dave again, thank you for thinking of this, for spending your time thinking and then posting your ideas.