Jay4200

Veteran Member

- Joined

- Nov 23, 2005

- Messages

- 2,053

- Location

- Hudson/Weare, NH

- Tractor

- L4200GST w/ LA680 & BX2200D w/ LA211

Well yesterday was kind of lost, it was raining so hard I didn't want to move the tractor across the lawn to the garage but today is a different story

I mounted the blower & ran it up some to be sure there were no issues. It's a beast. I looked it up on Normand's site & it says it weighs just over 600 lbs but then it has the hydraulics added that must add another 50-60 lbs. I wasn't sure how the little L3400 would handle it but the 3 pt had no problems lifting it easily - even at idle. Just seems like a lot of weight hanging way back there.

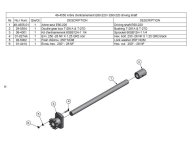

Now I'm (almost) ready for some serious gravel throwing. Speaking of stones, I see only one lil itty bitty shear bolt (on the drive shaft) of this brute. . . does that sound right???

There are two shear bolts, but the second is on the PTO shaft, I think. I found a 6-footer version of the same machine on CL this summer for similar $$, including the dual hydraulic remotes, although yours is in nicer shape. I integrated a valve set onto the blower since I didn't have remotes to run the hydraulics - a PITA at best.

I'm surprised that a 5 footer covers your wheel track. I needed 6' to cover my L4200 rears, which made it far harder (and more $$$) to find a used machine - not many out there bigger than 5'.

I have a parts manual from Normand that includes your blower and accys (in pdf format) if you want it - PM me and I'll e-mail it to you.

JayC