The builders for my pole barn made some mistakes installing the sliding door and I have a few questions for the members here.

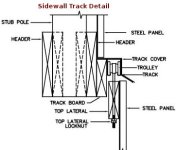

Should the top track trim / cover be installed behind the siding. I thinks so, since this should act as flashing to keep rain off the track and the top of the door.

Should the top track itself be bolted to a board and siding fitted around it? Right now they put the track up against the metal siding and ran screws through it. I really don't think this is right as it is sitting on the ribs in the metal.

Should the top of the sliding door be covered by the track trim / cover? It seems like it should otherwise rain would blow in over the top of the door.

I requested a bottom track for the door and what they put in is a metal channel screwed in at the bottom of the outside of the wall. There are no guides, post or wheels in the door that run in this track. Kind of defeats the purpose of having a bottom track.

I have spoken to the builders and I am waiting to hear how they propose to resolve the problems with the door. If anyone has detailed pictures of their sliding door installations, track, flashing, bottom tract, trim etc. I would really appreciate if you could post a few.

I know what they have done so far isn't correct and I believe they will take care of it, but I want to make sure it is done right. I haven't installed any sliders myself and have only seen a few in person, but I never really paid attention to it. Any advice or pictures are greatly appreicated!

Should the top track trim / cover be installed behind the siding. I thinks so, since this should act as flashing to keep rain off the track and the top of the door.

Should the top track itself be bolted to a board and siding fitted around it? Right now they put the track up against the metal siding and ran screws through it. I really don't think this is right as it is sitting on the ribs in the metal.

Should the top of the sliding door be covered by the track trim / cover? It seems like it should otherwise rain would blow in over the top of the door.

I requested a bottom track for the door and what they put in is a metal channel screwed in at the bottom of the outside of the wall. There are no guides, post or wheels in the door that run in this track. Kind of defeats the purpose of having a bottom track.

I have spoken to the builders and I am waiting to hear how they propose to resolve the problems with the door. If anyone has detailed pictures of their sliding door installations, track, flashing, bottom tract, trim etc. I would really appreciate if you could post a few.

I know what they have done so far isn't correct and I believe they will take care of it, but I want to make sure it is done right. I haven't installed any sliders myself and have only seen a few in person, but I never really paid attention to it. Any advice or pictures are greatly appreicated!