Bison, are you out there? I just started tearing down my 4500 and replacing the tracks. I must say that I believe the 4500 is an extremely easy machine to work on the undercarriage. Granted I haven't dug into the axle assemblies yet so I'm not familiar with what Tags is talking about yet. I did take the track off one side and I have two of the axle tubes removed. Here's what I found. It only took me a couple of hours to remove one track. Now that I've done it I think I could have it off in an hour. Most of that time would be spent blocking up the machine. The undercarriage is extremely easy to take apart and the track was extremely easy to remove. I really like the fact that ASV almost always used through bolts with nuts on this undercarriage. This makes it much easier to remove rusty bolts because you can always cut them off without ruining threaded holes. The good news is that all my wheels on both sides turn and spin very freely. I think this means that all the bearings are in good shape. This should also mean that my axle shafts will be in good shape. I have two axle assemblies removed so far and they are in excellent shape. I do have two axle seals that I know leak so I'm sure I'm looking at taking those axle tubes apart. I think I will replace the seals while apart. Also, I see no cracks or damage to any undercarriage parts such as the frame. I don't think this machine was abused. Some questions for Bison or anyone else with knowledge of this machine:

1. I assume you would recommend filling the tubes with grease rather than gear lube?

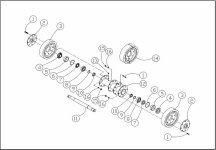

2. Are there any tricks to removing the seals and bearings from the axles? Can one just press the shaft one direction to remove the seals and bearing on one side and turn it around and go the other way? My bearing and seals are different from those on the 4810 so your experience may not apply exactly but I'd like to know how you took yours apart.

3. With 1800 hours on this machine should I take apart axle tubes that are not currently leaking?

1. I assume you would recommend filling the tubes with grease rather than gear lube?

2. Are there any tricks to removing the seals and bearings from the axles? Can one just press the shaft one direction to remove the seals and bearing on one side and turn it around and go the other way? My bearing and seals are different from those on the 4810 so your experience may not apply exactly but I'd like to know how you took yours apart.

3. With 1800 hours on this machine should I take apart axle tubes that are not currently leaking?