Not really a lot to take appart.

all you got to do is pop the hood and you can kill the engine with the lever. I was just advising to pull the panels off to help him find the injector pump, and thus the lever. Once he knows where it is, he can reach it with just the hood popped.

And IMO, An engine that will not shut down is NOT considered an emergency. Just an incovience. In the event of an emergency situation, you would use the key-switch. But a failed cut-off relay all by itself IMO doesnt constitute an "emergency".

And it it was indeed an emergency and the key didnt work, dumping the clutch in H range does wonders:thumbsup:

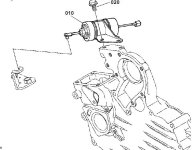

:thumbsup:LD1Found it! I took the side panel off and sure enough there it is. It is a spring loaded lever. I turned the tractor on and moved the lever over and Walla! The tractor shut down immediately. Now that I know where it is, it will be easy to reach under there and turn it off. I may put a small extension on it and paint it redso It is easy to see and locate. Just in case I have to tell someone else how to shut it down in an emergency that may be using my tractor.

Thanks for helping me out.

I also did call Kubota at the Northern branch in Ohio. I am happy to report that the assistant manager of service, Dave, called back and was very knowledgeable and helpful regarding this whole situation. He did reaffirm that the HST switch is not put in the tractors in the USA, but use the same wiring harness and suspects that there is a short somewhere in that wire. I am now going to go out to try and find that. Thanks again for all the help on this forum. This is very valuable.