Panik

Platinum Member

- Joined

- Mar 29, 2013

- Messages

- 508

- Tractor

- Kubota bx2360

So not too long ago I purchased a 18' (16' + 2' dovetail) P&T 7K car hauler (2k trailer weight, 5K capacity) with brakes on both axles. It was purchased to haul our BX2360 as well as for general purpose hauling.

For the little use it has seen so far it works well for its purchased purpose. It has a little more cross frame flex than I would necessarily like, but that issue as well as possibly reinforcing the cross members are a potential project for down the road....... weight dependent.

In any case one of things I did not like was the factory wiring job - scotch lock and wire wrapped around axle frames. One of the first things I have done is to start to re-work the wiring using junction boxes and heavier gauge SJOOW wire. I also have added LED rear ID lights, as well as side and front marker lights. Unfortunately I am getting in a bit over my head and could used some advice on a couple of points:

Please forgive me if the questions are goofy I've been doing so much reading that things are starting to run together.

I would like to have the side marker lights function as turn indicator lights however I am not sure I completely understand how to do this. They trailer will be connected to a jeep commander with 7 way plug. Can I just simply run the left and right middle markers off of the left and right turn wires? If so will they also come on with the brake lights? I am okay with this if it happens for simplicity sakes - I know there is a relay based solution for that issue, but I don't want to attempt it at the moment unless necessary.

Also given that I am using LED lights for the markers and dual filaments for the rear brake and turn indicators do I need some form of converter to slow the flash rate of the LED's?

2) I am adding a storage box onto the front of the trailer because I am really tired of having to throw chains, tie downs, etc into the back of the jeep. Yes, I know first world woes . Anyways the tongue on the trailer is pretty short so I do not think I will be able to mount the box in front of the deck for fear of bashing up the jeep. I could be wrong on this and need to test things. As well I don't want to lose deck space so...... Does anyone see any issues with mounting the box on the front rail of the trailer and building a small angle iron frame to support it?

. Anyways the tongue on the trailer is pretty short so I do not think I will be able to mount the box in front of the deck for fear of bashing up the jeep. I could be wrong on this and need to test things. As well I don't want to lose deck space so...... Does anyone see any issues with mounting the box on the front rail of the trailer and building a small angle iron frame to support it?

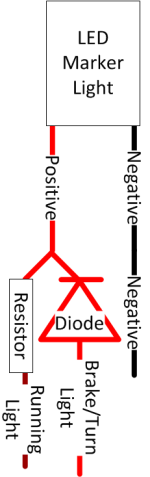

3) Lurking around Pirate4x4 I saw where someone had run wiring so that when they had a vehicle on their trailer they could plug the towed vehicle into the trailer wiring harness and the run the brake and turn lights via the vehicle doing the towing. I would love to do this with my tractor. I believe the individual who did this used diodes (purchased from and RV) to prevent issues with current going the wrong direction. It seem like a pretty simple mod - is there anything I am missing?

For the little use it has seen so far it works well for its purchased purpose. It has a little more cross frame flex than I would necessarily like, but that issue as well as possibly reinforcing the cross members are a potential project for down the road....... weight dependent.

In any case one of things I did not like was the factory wiring job - scotch lock and wire wrapped around axle frames. One of the first things I have done is to start to re-work the wiring using junction boxes and heavier gauge SJOOW wire. I also have added LED rear ID lights, as well as side and front marker lights. Unfortunately I am getting in a bit over my head and could used some advice on a couple of points:

Please forgive me if the questions are goofy I've been doing so much reading that things are starting to run together.

I would like to have the side marker lights function as turn indicator lights however I am not sure I completely understand how to do this. They trailer will be connected to a jeep commander with 7 way plug. Can I just simply run the left and right middle markers off of the left and right turn wires? If so will they also come on with the brake lights? I am okay with this if it happens for simplicity sakes - I know there is a relay based solution for that issue, but I don't want to attempt it at the moment unless necessary.

Also given that I am using LED lights for the markers and dual filaments for the rear brake and turn indicators do I need some form of converter to slow the flash rate of the LED's?

2) I am adding a storage box onto the front of the trailer because I am really tired of having to throw chains, tie downs, etc into the back of the jeep. Yes, I know first world woes

3) Lurking around Pirate4x4 I saw where someone had run wiring so that when they had a vehicle on their trailer they could plug the towed vehicle into the trailer wiring harness and the run the brake and turn lights via the vehicle doing the towing. I would love to do this with my tractor. I believe the individual who did this used diodes (purchased from and RV) to prevent issues with current going the wrong direction. It seem like a pretty simple mod - is there anything I am missing?