LD1

Epic Contributor

I think I forewarned everyone that I would be asking lots of questions about my upcoming bard build.:laughing: This is just another...

I know we touched on this topic in one of the other threads, but would like to focus on JUST the header.

The building is going to be a 40x72 with 16' doors on the eave (load bearing) sides. With 8' OC posts, over the door will be omitting one post. So a 16' span, with a truss smack dab in the middle. All of the span tables and calculators I have came across all deal with distributed loads, and NOT point loads.

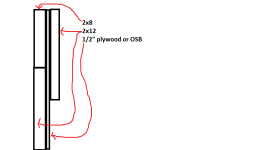

Further more, I am having a hard time finding any data on how much strength plywood or OSB add to a mulit-piece beam. I have up to 24" of depth to work with, as the walls will be 14' and the door only needs to be 12' high.

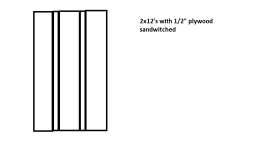

So I am looking for the most cost effective way to get the strength needed. From the reading I have done, several sites mention that adding plywood does NOT add as much strength as people believe.Several sources state that Using 3 2x12's with 2 ripped sections of plywood in between gets 5.5" wide (to match the post), but using an extra 2x12 would be stronger than the plywood. (and 0.5" wider too). Further they go on to say that the plywood is mainly just used to get the beam the same width as the wall.

And from further reading, the modulus of elasticity of several types of plywood all seem to be about the same as SYP lumber. (1.6 million). So that seems to confirm that.

Not really looking to go the route of layering in steel plate, cause that increases difficulty of construction. And if I was going steel, I would just size a beam and be done.

Given the building span, truss spacing, and snowload, I need a 16' header that can support 6000lbs right in the middle. (Thats 30 PSF total load plus 1000# just to be safe). I have got some ideas floating around in my head, I'll sketch them up and post. But looking for ideas as to what others with similar span and loading have in their buildings for a load bearing wall?

I know we touched on this topic in one of the other threads, but would like to focus on JUST the header.

The building is going to be a 40x72 with 16' doors on the eave (load bearing) sides. With 8' OC posts, over the door will be omitting one post. So a 16' span, with a truss smack dab in the middle. All of the span tables and calculators I have came across all deal with distributed loads, and NOT point loads.

Further more, I am having a hard time finding any data on how much strength plywood or OSB add to a mulit-piece beam. I have up to 24" of depth to work with, as the walls will be 14' and the door only needs to be 12' high.

So I am looking for the most cost effective way to get the strength needed. From the reading I have done, several sites mention that adding plywood does NOT add as much strength as people believe.Several sources state that Using 3 2x12's with 2 ripped sections of plywood in between gets 5.5" wide (to match the post), but using an extra 2x12 would be stronger than the plywood. (and 0.5" wider too). Further they go on to say that the plywood is mainly just used to get the beam the same width as the wall.

And from further reading, the modulus of elasticity of several types of plywood all seem to be about the same as SYP lumber. (1.6 million). So that seems to confirm that.

Not really looking to go the route of layering in steel plate, cause that increases difficulty of construction. And if I was going steel, I would just size a beam and be done.

Given the building span, truss spacing, and snowload, I need a 16' header that can support 6000lbs right in the middle. (Thats 30 PSF total load plus 1000# just to be safe). I have got some ideas floating around in my head, I'll sketch them up and post. But looking for ideas as to what others with similar span and loading have in their buildings for a load bearing wall?