So I tried what Djames55 suggested and found my setup behaves like his. With the loader arms fully extended (bucket at highest possible point) and the rear 3PT lever all the way forward (rear implement lowered as far as it can go so there's no weight on the 3PT) as in the attached photo, the bucket cylinders can roll the bucket toward me but it will NOT extend the cylinders. It just won't do it. Not slowly, not eventually, it just won't go. If I raise the 3PT hitch so that the rear implement is off the ground those same cylinders WILL extend. No idea what's going on but I think putting a gauge in the system will help identify things. When I do that I'll post the results.

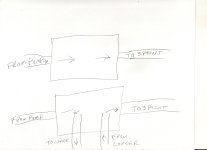

woolyAcres, I don't think you fully understand what I was trying to say... I only have to change the position of my 3 point to make my loader lift max weight... My 3 point has 600 lbs on the back of the tractor for a counter weight... If I have my 3 point down no weight on it my loader will only pick up 300 or 400 LBS... But if I raise my 3 point up as high as it will go with the 600 lbs counter weight... Not the loader lift arms... I can lift 1000+ LBS with the loader... If I need to curl down or up with the loader bucket, I have to lower my 3 point down 1 or 2 inches... To make it curl... I agree with Winston "that back pressure feeding back to the 3 point...That is the reason it is recommended to plumb loaders with power beyond. To eliminate back pressure." My tractor did NOT have a loader when I bought it... I installed it myself with the parts and per instructions from Hoye Tractor Parts... Like this >>>Yanmar Tractor Parts HYDRAULIC ADAPTER - ADD A LOADER / LOG SPLITTER But I don't know how to install and plumb a loaders with power beyond... I have got real good working my 3 point and loader valve to use my tractor... I always leave my 3 point down 1 or 2 inches from max lift to use my lift and curl on my loader... If I need more lifting power with my loader I lift up my 3 point to max height...