BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

"I like your installation with hard lines at the valves. What do the two valves do? Are those lines stainless?"

Right now, the 2 valves don't do ANYTHING - when the dust settles (eventually) they will control whatever extras I have mounted on the FEL - when the grapple is on, one of them will control that - when the hydraulic sickle bar is on, I already have a flow control for that but the two solenoids will control articulation cylinders on 2 separate joints to change reach and angle - both will be inserted in the bucket curl circuit so I'll have the choice of either curl, articulation 1 or 2.

Yeah, the hard lines are stainless, but those and the mounting plate will need to be re-done, since some dummy mounted the solenoid valves BACKWARD - trying to keep the solenoids and electrical protected. When it's finished the solenoids will need to be on the opposite end, and I'll fab a shield from 1/4" plate as well as a reversed mounting bracket (duh....)

- trying to keep the solenoids and electrical protected. When it's finished the solenoids will need to be on the opposite end, and I'll fab a shield from 1/4" plate as well as a reversed mounting bracket (duh....)

"Just price 1/2 inch JIC flareless connectors...........at $23.86 each!

27208-08-08 | 1/2" JIC Male x 1/2" Flareless

But the cost of the items seperate, the way you did it, is total....$$5.26. What is the difference? Or am I missing something?"

Yes - for some reason, male JIC's often cost more than females - your link is for a MALE JIC end, and the individual pieces I linked are just the female JIC sleeve with a female nut - they're installed by gently screwing the nut onto a male JIC fitting (with the sleeve INSIDE the nut), then inserting the tubing into both and finally tightening the nut onto the male JIC fitting til the sleeve is crimped onto the tube. IMO, the ones you linked are grossly overpriced so I've used the separate components to make a female JIC, then if you need that end to be MALE, just get a male/male JIC and screw THAT into the tube-mounted female.

In 1/2" size, that male/male JIC adds a whole $1.07, for a whopping total of $6.33 instead of $23.86...

JIC 37° Tube Union (Steel)

If you're just getting into Swage-lok stuff at work, they have VERY specific tightening instructions that vary somewhat with the size - the reason for that is removability - if you don't tighten the fitting ENOUGH, it will leak. IF you tighten it to spec, if won't leak and you can unscrew it and put it back together easily with no leaks.

If you tighten it TOO much, you will upset the end of the tubing that seats inside the fitting too much, swelling it so it won't come out. If you tighten it THREE much it's possible to get a stress crack in the fitting body.

it's possible to get a stress crack in the fitting body.

These flareless fittings are NOT Swage-lok, but work similarly - with both, you want them tightened just til you can see a SLIGHT deformation where the sleeve fits around the tubing - less, and they'll come apart under pressure; too much, and they can deform and leak.

When I first started using the flareless fittings, I bought a few spares so I could screw up a couple as a learning experience - I found you can get it figured out in 2-3 tries by just paying attention, knowing approximately how much to tighten, and looking at where the crimped sleeve joins the tubing.

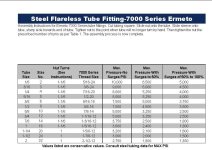

Here's a different brand's chart that worked fine for me... Steve

Right now, the 2 valves don't do ANYTHING - when the dust settles (eventually) they will control whatever extras I have mounted on the FEL - when the grapple is on, one of them will control that - when the hydraulic sickle bar is on, I already have a flow control for that but the two solenoids will control articulation cylinders on 2 separate joints to change reach and angle - both will be inserted in the bucket curl circuit so I'll have the choice of either curl, articulation 1 or 2.

Yeah, the hard lines are stainless, but those and the mounting plate will need to be re-done, since some dummy mounted the solenoid valves BACKWARD

"Just price 1/2 inch JIC flareless connectors...........at $23.86 each!

27208-08-08 | 1/2" JIC Male x 1/2" Flareless

But the cost of the items seperate, the way you did it, is total....$$5.26. What is the difference? Or am I missing something?"

Yes - for some reason, male JIC's often cost more than females - your link is for a MALE JIC end, and the individual pieces I linked are just the female JIC sleeve with a female nut - they're installed by gently screwing the nut onto a male JIC fitting (with the sleeve INSIDE the nut), then inserting the tubing into both and finally tightening the nut onto the male JIC fitting til the sleeve is crimped onto the tube. IMO, the ones you linked are grossly overpriced so I've used the separate components to make a female JIC, then if you need that end to be MALE, just get a male/male JIC and screw THAT into the tube-mounted female.

In 1/2" size, that male/male JIC adds a whole $1.07, for a whopping total of $6.33 instead of $23.86...

JIC 37° Tube Union (Steel)

If you're just getting into Swage-lok stuff at work, they have VERY specific tightening instructions that vary somewhat with the size - the reason for that is removability - if you don't tighten the fitting ENOUGH, it will leak. IF you tighten it to spec, if won't leak and you can unscrew it and put it back together easily with no leaks.

If you tighten it TOO much, you will upset the end of the tubing that seats inside the fitting too much, swelling it so it won't come out. If you tighten it THREE much

These flareless fittings are NOT Swage-lok, but work similarly - with both, you want them tightened just til you can see a SLIGHT deformation where the sleeve fits around the tubing - less, and they'll come apart under pressure; too much, and they can deform and leak.

When I first started using the flareless fittings, I bought a few spares so I could screw up a couple as a learning experience - I found you can get it figured out in 2-3 tries by just paying attention, knowing approximately how much to tighten, and looking at where the crimped sleeve joins the tubing.

Here's a different brand's chart that worked fine for me... Steve