tech7weld

New member

I am in the formative stages of designing an overhead bridge crane for my shop. With assistance from other threads on this forum and Engineering ToolBox I ran some basic calculations on the bridge beam. The following basis was used:

Beam Size: S8X23

Beam Span: 20ft (240")

Load: 2500 lbs

Calculation: Single Center Load

Based on the above, I came up with a deflection of 0.382" This seems excessive. I am missing a decimal somewhere? Can someone here verify?

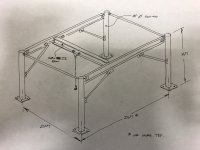

Thanks in advance. Sketch of proposed design is depicted below.

Beam Size: S8X23

Beam Span: 20ft (240")

Load: 2500 lbs

Calculation: Single Center Load

Based on the above, I came up with a deflection of 0.382" This seems excessive. I am missing a decimal somewhere? Can someone here verify?

Thanks in advance. Sketch of proposed design is depicted below.