You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beware of possible issues when installing some LED lights on your tractor

- Thread starter W8BYA

- Start date

- Views: 22019

More options

Who Replied?

/ Beware of possible issues when installing some LED lights on your tractor

#61

Citydude

Super Member

I bluetooth music from my phone. The radio stations available to me aren't worth listing to.

k0ua

Epic Contributor

6 pages in. Did I missed the fix for the radio losing reception when I turn the LED lights on?

I will nutshell it for you... Yes the OP has come up with a pretty effective custom designed filter. BUT he is waiting on a commercially available (for a pretty good price) filter he wants to test to be able to help others. This filter will go in series with the + and - power feeds to the lights to hopefully suppress the "trash" that is coming out of the power supply of the LED lights.

Last edited:

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

I didn't read through all 60+ posts, but are these LED lights add-on? In their own housing...probably plastic?

Wonder how the interference would be affected if they were housed in a grounded metal box?

Wonder how the interference would be affected if they were housed in a grounded metal box?

W8BYA

Silver Member

I didn't read through all 60+ posts, but are these LED lights add-on? In their own housing...probably plastic?

Wonder how the interference would be affected if they were housed in a grounded metal box?

The LED lights are add-ons. It is sorta funny but I will note that NH now sells these exact same lights as an accessory. They really do look 100% identical. They have 3 different models available (small round, these square, and a bar style). I purchased these off e-bay and installed them in about 5 minutes. Several weeks later I got a post card from NH describing these different LED lights they now have available. Their cost is around $60/pair, my cost off e-bay was about $13. I wish I had a pair of the NH lights so I could rip it open to verify they really are identical inside & out.

The LED light assemblies are surprisingly well made, heavy, and water tight. They are thick die-cast aluminum with large, integral cooling fins in the back. The only side which is not part of the aluminum case and open is the front where the LED lights are.

I have sniffed the LED lights with small E & H-field probes and while there is some EMR (electromagnetic radiation) coming out the front of the assembly the overwhelming amount of RFI generated by the switching power supply is coming out in the form of conducted emissions on the DC power lines.

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

I'm a retired electronic technician also, not close to your expertise, but then I wonder about if a grounded metal case, what if front lens covered by metal screen wire, maybe copper screen? Also grounded and it may not affect light output much (whole thing in a Faraday cage).

Then if feedback on power line maybe isolation series diode with filter cap to ground near light?

Then if feedback on power line maybe isolation series diode with filter cap to ground near light?

W8BYA

Silver Member

I'm a retired electronic technician also, not close to your expertise, but then I wonder about if a grounded metal case, what if front lens covered by metal screen wire, maybe copper screen? Also grounded and it may not affect light output much (whole thing in a Faraday cage).

Then if feedback on power line maybe isolation series diode with filter cap to ground near light?

It's great that you are thinking about the problem and possible cures. The level of overall radiation emitted directly from the internal circuitry (and escaping from the front of the assembly) is negligible compared to the level of RFI conducted onto the power lines.

In an earlier post I showed a plot showing the relative amplitude and very wide frequency response of the RFI. The switcher operates at around 477 kHz and it's a real screamer with very fast rise & fall times. There is over 1.6 V(p-p) RFI riding on top of the 13.8 VDC power line ! I was debating doing some wave shaping of the internal clock & pulse signals which I know would help but not totally eliminate the problem.

The level of the RFI that ends up on the power lines is huge and extends well past several hundred MHz. I am not 100% sure I understand your approach to using feedback & diodes. But if I think I understand, I believe the problem with using diodes in series with the lines to block the RFI is that they will work fine at DC but because of the capacitance of the PN junction they will provide a pretty effective path at RF frequencies and let the RFI pass right thru. Even 20 pF or so from a reverse biased junction will provide a pretty low reactance at VHF. Also a simple capacitor cannot provide enough filtering as the issue is one made up of common-mode and differential RF currents, so it will need more then several components.

In the end, based on some simple fixes I tried earlier (like shunt & bypass caps with series inductors, etc, etc) I think it is going to take a more robust design to tame this RFI. Given the low cost of some commonly available commercial power line filters that are really well designed that is the approach I am going to take or at least try out.

The prototype filter I did design and try out was quite effective and resembles the commercial filters I have on order. As soon as they come in I will test them out and let you know how well they worked. They can be had for about $10 a pop which is hard to beat IMO. I picked several models that are readily available so that others would be able to order them as well if they chose to go the same route as me.

k0ua

Epic Contributor

Fingers crossed that the commercial RFI filter will do the trick. While we are waiting, let me tell you a story.

I have a lot of "electronic things" in the house, and included was a 16 port 10/100 data switch which did not emit a horrible amount of RFI and its little switch mode power supply was fairly clean. At least all of this did not prevent my normal HF radio fun. Then one day all of the bands up to and including 6 meters (50 Mhz) were covered with wall to wall broad band noise and spikes on the scope). I mean it wiped out the entire range. So I started the typical hunt, first get radio on battery power, then turn off power to house. That killed it, then started breaker by breaker.

Being a smart coyote, I turned off the breaker to the office (where the data equipment is located) first. Oh, boy, now we are getting somewhere. Then started to unplug things one by one. So this little data switch's power supply was the culprit. But the good part was that the power supply which had been reasonably clean was still operating the data switch JUST FINE!. But it was now the trashmaster of all time. So what went south in it? Who knows. I replaced it with another power supply I found on the internet and all was well. As well as before because wired ethernet itself makes a few birdies. I eventually got rid of all of the wired ethernet and went totally wireless, which is the preferred method.

I kept that offending power supply around for a few years thinking I might slip it into an outdoor outlet of someone that I really really hated to ruin their TV and radio reception, but decided that even I am not that hateful, so I pitched it.

I do believe you could have put and "antenna" some more wire on the power supply cord, and keyed it on and off with a morse code key, and communicated with it. I have never seen anything put out so much powerful RF energy as a consequence to its normal operation as a power supply.

I have a lot of "electronic things" in the house, and included was a 16 port 10/100 data switch which did not emit a horrible amount of RFI and its little switch mode power supply was fairly clean. At least all of this did not prevent my normal HF radio fun. Then one day all of the bands up to and including 6 meters (50 Mhz) were covered with wall to wall broad band noise and spikes on the scope). I mean it wiped out the entire range. So I started the typical hunt, first get radio on battery power, then turn off power to house. That killed it, then started breaker by breaker.

Being a smart coyote, I turned off the breaker to the office (where the data equipment is located) first. Oh, boy, now we are getting somewhere. Then started to unplug things one by one. So this little data switch's power supply was the culprit. But the good part was that the power supply which had been reasonably clean was still operating the data switch JUST FINE!. But it was now the trashmaster of all time. So what went south in it? Who knows. I replaced it with another power supply I found on the internet and all was well. As well as before because wired ethernet itself makes a few birdies. I eventually got rid of all of the wired ethernet and went totally wireless, which is the preferred method.

I kept that offending power supply around for a few years thinking I might slip it into an outdoor outlet of someone that I really really hated to ruin their TV and radio reception, but decided that even I am not that hateful, so I pitched it.

I do believe you could have put and "antenna" some more wire on the power supply cord, and keyed it on and off with a morse code key, and communicated with it. I have never seen anything put out so much powerful RF energy as a consequence to its normal operation as a power supply.

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

It's great that you posted this also and all the work you're doing to solve it. Wow! This "There is over 1.6 V(p-p) RFI riding on top of the 13.8 VDC power line !"

is amazing and explains so many problems people (may) experience using LEDs.

Before retiring I was a troubleshooter, primarily consumer electronics.

The diode/cap idea was a simple isolation thought which would drop LED supply by about 0.65-0.7V (with it's smps wouldn't affect light output).

It would be more complexity but a separate battery such as an inexpensive (like Everstart 230 cca $22), LEDs powered by it, that battery then charged by isolation diode from tractor alternator.

Me...I'd be thinking of ditching LEDs in favor of halogen!

is amazing and explains so many problems people (may) experience using LEDs.

Before retiring I was a troubleshooter, primarily consumer electronics.

The diode/cap idea was a simple isolation thought which would drop LED supply by about 0.65-0.7V (with it's smps wouldn't affect light output).

It would be more complexity but a separate battery such as an inexpensive (like Everstart 230 cca $22), LEDs powered by it, that battery then charged by isolation diode from tractor alternator.

Me...I'd be thinking of ditching LEDs in favor of halogen!

W8BYA

Silver Member

That's both funny and scary at the same time hi-hi. The first thing that comes to my mind is that because you mentioned it was not a horrible noise maker initially and then all of of a sudden it was.....to me that implies that they may have tried to wave shape the noisy square wave oscillator and associated pulses to reduce their rise & fall times.

Slowing them down will have a HUGE impact on the RFI profile of radiated & conducted emissions. If a shunt cap failed open (or became disconnected) that was used to slow the edges down it could explain the sudden increase in RFI.

As a side note (in my real & former life and profession) I was in tempest engineering. Can't go into details but many decades ago I used source-suppression as a very elegant and economical way to tempest harden equipments that had to meet very strict emission limits.

Slowing them down will have a HUGE impact on the RFI profile of radiated & conducted emissions. If a shunt cap failed open (or became disconnected) that was used to slow the edges down it could explain the sudden increase in RFI.

As a side note (in my real & former life and profession) I was in tempest engineering. Can't go into details but many decades ago I used source-suppression as a very elegant and economical way to tempest harden equipments that had to meet very strict emission limits.

W8BYA

Silver Member

It's great that you posted this also and all the work you're doing to solve it. Wow! This "There is over 1.6 V(p-p) RFI riding on top of the 13.8 VDC power line !"

is amazing and explains so many problems people (may) experience using LEDs.

Before retiring I was a troubleshooter, primarily consumer electronics.

The diode/cap idea was a simple isolation thought which would drop LED supply by about 0.65-0.7V (with it's smps wouldn't affect light output).

It would be more complexity but a separate battery such as an inexpensive (like Everstart 230 cca $22), LEDs powered by it, that battery then charged by isolation diode from tractor alternator.

Me...I'd be thinking of ditching LEDs in favor of halogen!

I'm a little intrigued by the diode/cap idea, would you be willing to e-mail me a sample schematic drawn on the back of a napkin of a simplified example of it's execution? My e-mail is w8bya at mchsi dot com. I would like to see that and possibly mess around with it purely because I'm a geek and miss doing engineering work so it would be fun some cold wintery night.

Also, I can understand wanting to ditch LED's all together but we need to remember that not everyone has issues with them because as noted earlier it takes two to tango.....you need a trouble maker but you also must have something susceptible to that trouble maker. If your equipment already has filtering or simply is not susceptible then heck keep using them. They are very bright and draw way less power. And they will outlast the tractor and any halogen bulbs <g>.

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

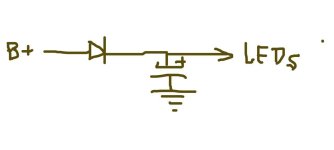

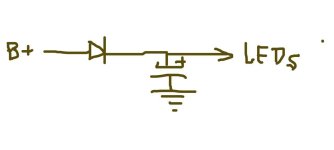

This is a simple draw app (my finger is shaky )...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.

)...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.

Of course this would be close to LED, maybe one for each. With your o-scope probe here, value of cap for lowest p-p noise level. Who knows...1,000 ufd @ 25v, a low esr hi temp quality cap?

)...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.

)...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.Of course this would be close to LED, maybe one for each. With your o-scope probe here, value of cap for lowest p-p noise level. Who knows...1,000 ufd @ 25v, a low esr hi temp quality cap?

W8BYA

Silver Member

This is a simple draw app (my finger is shaky)...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.

Of course this would be close to LED, maybe one for each. With your o-scope probe here, value of cap for lowest p-p noise level. Who knows...1,000 ufd @ 25v, a low esr hi temp quality cap?View attachment 629111

Ok but remember it is not the LED's that are causing the issue. It is the power supply that is generating the B+ (BTW you just gave your age away <g>).

We are worried about what the power supply (that is generating the B+ in this case) is injecting back onto the raw DC supply lines ! There is a country mile of electronics between the LED's (load) and the DC supply voltage.

k0ua

Epic Contributor

I figured what ever noise suppression components the OEM had put in the little power supply had failed in an open condition. (like a capacitor) and that was why all of a sudden one day, it was trash city coming from the little supply. I probably should have kept it as a lab curiosity, but I was afraid it would get mixed in with all the other little "wall warts" I have laying around.

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

I haven't read through all the 70+ posts, but my understanding was you have an New Holland tractor that all was well. You replaced the factory halogen lights with LED lights. This created noise problems because the LED lights have their own smps which are adding that 1.6vp-p ("pulse, noise") onto DC.

Now instead of "clean" DC (except when running whatever little bit alternator pulses) you have this which affects radio, possibly computer, etc.

Isolation diode and filter cap hopefully would block this feedback from LED lights back onto tractor power line.

Am I correct?

Now instead of "clean" DC (except when running whatever little bit alternator pulses) you have this which affects radio, possibly computer, etc.

Isolation diode and filter cap hopefully would block this feedback from LED lights back onto tractor power line.

Am I correct?

W8BYA

Silver Member

I haven't read through all the 70+ posts, but my understanding was you have an New Holland tractor that all was well. You replaced the factory halogen lights with LED lights. This created noise problems because the LED lights have their own smps which are adding that 1.6vp-p ("pulse, noise") onto DC.

Now instead of "clean" DC (except when running whatever little bit alternator pulses) you have this which affects radio, possibly computer, etc.

Isolation diode and filter cap hopefully would block this feedback from LED lights back onto tractor power line.

Am I correct?

You have 99% of it correct. Imagine the 13.8 VDC from the tractor feeding a SMPS. The output from the SMPS feeds the individual LED lights. The SMPS and LED's are all inside a die-cast aluminum enclosure. The issue is the SMPS contaminates (inadvertently) the 13.8 VDC supply (INPUT) voltage from the tractor.

Filtering the DC voltage after the SMPS going to the LED's would not help matters. We need to filter between the SMPS and the tractors 13.8 VDC.

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

I understand and we're on the same page.

Ok...

"The SMPS and LED's are all inside a die-cast aluminum enclosure. The issue is the SMPS contaminates (inadvertently) the 13.8 VDC supply (INPUT) voltage from the tractor."

What I'm trying to say in that simple drawing is do not supply LEDs tractor power. Instead tractor power to anode of diode. Diode cathode to LED supply.

I'd use one diode+cap each light.

Instead of 13.8v going to each LED you would have 13.1v. Scope this point. Cap value for lowest noise.

Simple...hopefully this diode/filter cap prevents feedback from LED back to tractor "B+".

I used ECG125 diodes all the time. 1000 prv, 2.5A.

Ok...

"The SMPS and LED's are all inside a die-cast aluminum enclosure. The issue is the SMPS contaminates (inadvertently) the 13.8 VDC supply (INPUT) voltage from the tractor."

What I'm trying to say in that simple drawing is do not supply LEDs tractor power. Instead tractor power to anode of diode. Diode cathode to LED supply.

I'd use one diode+cap each light.

Instead of 13.8v going to each LED you would have 13.1v. Scope this point. Cap value for lowest noise.

Simple...hopefully this diode/filter cap prevents feedback from LED back to tractor "B+".

I used ECG125 diodes all the time. 1000 prv, 2.5A.

W8BYA

Silver Member

I understand and we're on the same page.

Ok...

"The SMPS and LED's are all inside a die-cast aluminum enclosure. The issue is the SMPS contaminates (inadvertently) the 13.8 VDC supply (INPUT) voltage from the tractor."

What I'm trying to say in that simple drawing is do not supply LEDs tractor power. Instead tractor power to anode of diode. Diode cathode to LED supply.

I'd use one diode+cap each light.

Instead of 13.8v going to each LED you would have 13.1v. Scope this point. Cap value for lowest noise.

Simple...hopefully this diode/filter cap prevents feedback from LED back to tractor "B+".

I used ECG125 diodes all the time. 1000 prv, 2.5A.

Ok I think I see the issue here. In your drawing you have it labeled as LED's. I think what you wanted to say was "LED Assembly" is that correct? You would like to see the diode and cap BEFORE the entire LED LIGHT ASSEMBLY....right?

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

Yes! Exactly right...now we're @100%!

mcfarmall

Veteran Member

- Joined

- Oct 1, 2015

- Messages

- 1,482

- Location

- Kalamazoo, MI

- Tractor

- Kubota M5660, Farmall C, JD 260 lawn tractor

Ran into a similar issue when I replaced the incandescent lamps in my travel trailer lights with LED's. My weather radio was essentially useless. I figured it out by process of elimination because the radio worked fine during the day but was junk after dark when I had lights on. Happened to walk out of the trailer when the radio was on and the interference went away when I turned off the light!