A shim - I've got a new very slightly sloping metal roof above. Historically snowfall here is 1" or less. I hail from Northern Vermont and have seen many a snowstorm over 30". With the messed up climate I'm concerned what a heavy snow would do to a roof designed for 6" so I shimmed the roof beam, little effort almost no cost.

<snip>

You can assemble pallet racking solo, but it is enormously easier with 2 people, BTW. Getting that first crossbar in place can be a real juggling act solo.

Yes two people make it easier, but I always rolled alone.

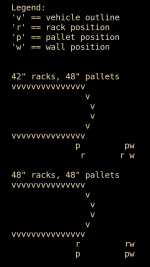

I usually set the first beam on two chairs, hooking into one upright that was leaned against the wall, then stand up the second upright and hook it in. I'd put the first beam in at chair height because if I put it in real low stuff twisted easily.

This forms the "rack", then I would hook more beams in at the heights I wanted for the first shelf. After it was hooked with 3 beams I would "slide" it into place.

Next put down stuff on the first shelf to stand on. The metal racks are great.

Then stand on the first shelf and put up a second shelf as high as I conveniently could at the spacing I wanted. The beams are heavy and I'm not a weight lifter.

Then repeat for higher shelves. Finally, after all shelves were up remove the first beam I put in.

Remember to put the first beam in so it's easy to take out.

So I got a quote from a place on pallet racks, but the carrier is "dock to dock, business to business". I asked if I was out of luck, told him I had a tractor with pallet forks, he queried his carrier and came back with "Carrier said if you can get the material off the truck the rate should be fine. The pallet will be 12 long and weigh 750 lbs."

A twelve foot pallet? Is that a thing? Don't think my 48" tractor pallet forks are going to do that. Anybody got additional light they can shed on this?

Drag it halfway off the truck then lift it in the middle.

But keep looking, the crashing economy should start forcing people to get rid of inventory.

I'd expect $40 to $50/upright and $25 to $30 per 12' beam, so a 24' run with 3 uprights and a total of 6 shelves be less than $500 off CL. But it will be easier to find 8' beams and have 3 sections.