SamWalton

Platinum Member

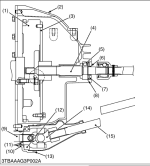

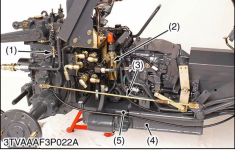

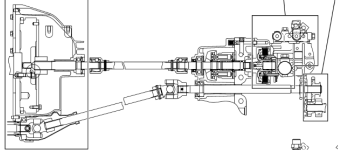

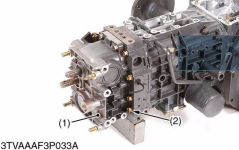

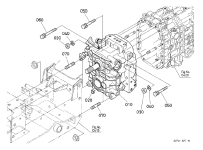

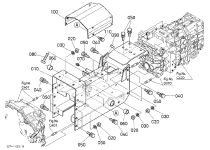

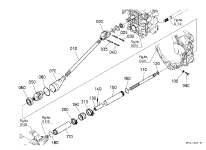

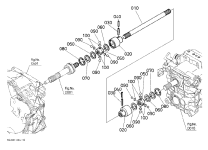

This U-joint failed and it looks like the repair is super expensive. I have been looking at alternatives to such a labor intensive repair. I am considering cutting out an opening in the plat from the bottom after removing the HST oil tank. Possibly using a plasma cutter to open for repair. This would make it easy to push out pins to remove U-joint. Two large bolts can be removed which support the front axel and wheels. This could give the extra movment of the drive shaft to allow removal and installation of the new U-joint. I am not sure if this will work but the photos and drawing look to support this theory. I have attached pictures and parts diagrams to show how these thing come together. Please, anyone who has done this repair, via dealer or otherwise please share your thoughts and opinions.

I have called the service department of our local Kubota dealer and they are unwilling to provide details on this repair. Also the service manual is not available on the internet and I may purchase a hard copy from the dealer.

I have called the service department of our local Kubota dealer and they are unwilling to provide details on this repair. Also the service manual is not available on the internet and I may purchase a hard copy from the dealer.

Attachments

-

2021-02-28 12-07-08_resize.JPG4.2 MB · Views: 446

2021-02-28 12-07-08_resize.JPG4.2 MB · Views: 446 -

2021-03-06 16-35-58_resize.JPG2.5 MB · Views: 464

2021-03-06 16-35-58_resize.JPG2.5 MB · Views: 464 -

2021-03-06 16-36-00_resize.JPG2.9 MB · Views: 519

2021-03-06 16-36-00_resize.JPG2.9 MB · Views: 519 -

2021-03-06 16-37-24_resize.JPG2.7 MB · Views: 481

2021-03-06 16-37-24_resize.JPG2.7 MB · Views: 481 -

2021-03-06 17-54-30_resize.JPG3.9 MB · Views: 390

2021-03-06 17-54-30_resize.JPG3.9 MB · Views: 390 -

B26 Tractor Parts Manual.pdf4 MB · Views: 204

-

FFDDBHDFHDFHDFHDFH_resize.png605 KB · Views: 382

FFDDBHDFHDFHDFHDFH_resize.png605 KB · Views: 382 -

SDFHXDFHFXDHDFHDFH_resize.png643.8 KB · Views: 377

SDFHXDFHFXDHDFHDFH_resize.png643.8 KB · Views: 377 -

sdsdgsdgsdgsdgsdgsdfgsdfg_resize.png403 KB · Views: 377

sdsdgsdgsdgsdgsdgsdfgsdfg_resize.png403 KB · Views: 377 -

ZSDGSDFGSDFGSDFGSDFGSDFGSDFGSDFG_resize.png470.9 KB · Views: 416

ZSDGSDFGSDFGSDFGSDFGSDFGSDFGSDFG_resize.png470.9 KB · Views: 416