BravoXray

Elite Member

- Joined

- Dec 17, 2019

- Messages

- 3,390

- Location

- Nothern Indiana

- Tractor

- Kubota BX2230, John Deere 430 Diesel

According to the assembly manual, the door gap is specified at 3/16" +-0.40".The joy of rebuilding an old car! The gap tolerances were pretty big back in the day.

I did some more shimming, pulling and pushing again this afternoon, and I think I got it to where the door gap is okay, and the rest of the alignment is acceptable. I'm going to have my friend, who is a body man take a look at it to see if it passes muster. It's going need a little bondo at the door gap to even out the area I had to recontour, but other than that it looks pretty good.

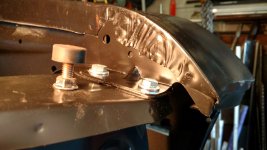

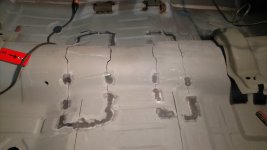

While I was looking for the seat tracks for the bucket seats, I came across a set of OEM seat mounts pulled out of another Nova. I bought them off Ebay a few years ago and forgot I had them. I spent a couple hours grinding off spot and MIG welds and hammering the inner mounts back into shape, and they fit pretty well, better than the aftermarket ones. The outer mounts have holes that bolt to the original bench seat mounts, so I don't have to figure out where to mount them. I also ordered a set of tracks for my application, and they'll be here tomorrow. Then I can get all the mounts in the correct position to weld them in place. Going to blast and prime the inner mounts first though.

Won't be able to do it tomorrow though, as I am going with a friend 270 miles north into Michigan to retrieve a '96 Dodge 2500 pickup with a 5.9 Cummins that he bought from another friend. It blew a head gasket and when torn down has four scored cylinders, so the engine is going to have to come out and be overhauled, even though it only has just over 100K on it. The owner doesn't want to spend $10-$12K they want to overhaul it, so he sold it to my local friend. Going to be a long day.