arto98607

Veteran Member

- Joined

- Aug 27, 2014

- Messages

- 1,589

- Location

- Southwest WA

- Tractor

- Kubota F3060, Grasshopper 721D, Ford 1310, John Deere 440 ICD, John Deere 300 & 430

Update

My plan all along was to service & dismantle my "new" 87 JD 430 enough to be able to inspect hydraulics, drive train, belts, drive shafts etc. in order to repair or replace whatever is needed, in order to make this into a long term use reliable garden tractor.

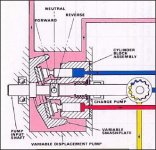

I have ran into a little difficulty when trying to remove the drive shaft rear yoke from the hydrostatic pump shaft!

It looks like it has never been removed previously, and has gotten stuck in the shaft (IE. rusted in place over 37 years). The front end is already loose and has cleared the engine V-belt pulley so that's not holding it.

I've been spraying WD40 over two or three days and trying to removed it gently, without hammering chisels in too hard in order to loosen the yoke.

Hammering chisels in too hard could easily damage the hydro pump outboard bearing & shaft surface.

Anyone else here who has had to deal with the same issue?

Panels removed for better access:

Two chisels, one on each side of the yoke split:

Lots of WD40, but so far it has not budged:

My plan all along was to service & dismantle my "new" 87 JD 430 enough to be able to inspect hydraulics, drive train, belts, drive shafts etc. in order to repair or replace whatever is needed, in order to make this into a long term use reliable garden tractor.

I have ran into a little difficulty when trying to remove the drive shaft rear yoke from the hydrostatic pump shaft!

It looks like it has never been removed previously, and has gotten stuck in the shaft (IE. rusted in place over 37 years). The front end is already loose and has cleared the engine V-belt pulley so that's not holding it.

I've been spraying WD40 over two or three days and trying to removed it gently, without hammering chisels in too hard in order to loosen the yoke.

Hammering chisels in too hard could easily damage the hydro pump outboard bearing & shaft surface.

Anyone else here who has had to deal with the same issue?

Panels removed for better access:

Two chisels, one on each side of the yoke split:

Lots of WD40, but so far it has not budged: