Shenandoah MF1760

Gold Member

- Joined

- Feb 12, 2021

- Messages

- 365

- Location

- Livingston, East Texas Piney Woods

- Tractor

- Massey Ferguson 2020 MF1760M

Yes. I have a 1760 with the 2814 FEL and I bent the same side you did.I have a Massey E 2860 with a FLX 2815 loader. Has anyone heard of the role bucket roll cylinders bending? I have a 40 year old John Deere and have had to replace the bucket because of the pressures I put on it and I’ve never bent a cylinder. This seems unbelievable that the cylinder rod could be so soft they would bend.

I believe mine happened when a branch came through my grapple and undid one of the QA levers resulting in the grapple falling off the FEL on one side while it was lifted.

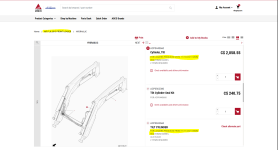

When I went to replace the cylinder I discovered that Massey had two different ones for the same FEL. One had a larger diameter rod and was obviously the replacement for the one that bent frequently. (insert inappropriate inflammatory language).

Being cheap I wasn't about to replace both cylinders although I wanted to. So, I gambled that all I needed was the rod assembly and not the entire cylinder. it's not too difficult to replace, but you won't find that construction type if cylinder on youtube so don't bother looking. That was two years ago and the repair has been working just fine.