I guess I should try to figure out what constitutes "pokes". I pretty much have to go on what they wrote, and the part I disagree with becomes my focus. I understand that people can have a bazillion hours experience, but there is a difference between genuine experience, and extrapolating it to a different machine or process. In any case I can see more clearly it's not so much the issue at hand, more the social aspects of a group discussion where it's not clear what the other guy really "knows".

Moss, aren't you even curious why the members who don't have 120v MIGs have such dogged determination to tell the others how they can or can't be used? Why don't you encourage those who have actually HAVE a 120v MIG to go at it, show members what can be done and let's see what happens? Wheres the harm in making test plates?

It's not a matter of 'can or can't be used'. It's a matter of should or shouldn't used. There's a difference.

I've used a torch and coat hangars many, many times on thin metal. I've tried it on thick metal, too in the field. Guess what? It worked. It looked great. It worked well.... until it blew apart and I could see where it failed. Good thing I wasn't under it. Wrong tool for the job.

I've removed large bolts with small wrenches. And I've broken small wrenches. I've never broken a big wrench.

I've back-fed generators in a power outage. But I would not recommend anyone do that.

The reason I don't encourage people that have 120v MIGs to push them beyond their manufacturers' recommendations is because (to put it bluntly) the repercussions of *'ing up can be severe.

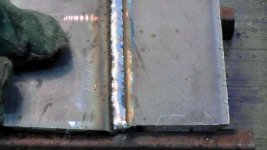

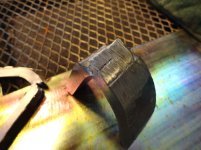

I have a 120v MIG. I love it on thinner stuff. Its fantastic. Other than tack welding, I don't use it for welding large stuff, except for a rare emergency repair, to get something to a place where I can repair it correctly. It doesn't penetrate and multiple passes by amatuers (like me) tend to look very pretty, but you have no way of knowing that they will hold until they break, which in some cases, is too late.

For most hobby users, home owners, farmers, etc... there is a place for it, however, I would definately NOT recommend a 120v MIG as a first welder for anyone. It is not versatile enough.