Hey all,

I hope everyone is staying safe with what is going on these days, etc.

I was recently using the old 1020D to grade the girlfriends driveway, and use it around her place to clear some land, grading work, etc.

I unfortunately blew one of the rear tires, and split the tube....was leaking ballast all the way as I was towing the old girl back home. I knew this day would come when the lack of maintenance in terms of rear tires and rims would no longer "wait", and become a headache. Just wish it happened at home. Oh well.

Got it home, jacked it up, and started to tear into it. I was able to remove both rear rims/tires, and separate the inner rims from the outer rim frame/tire. I loaded the two tires/outer rims onto the trailer to get new tires, tubes, and ballast fill.

Well, got to the tire shop, and they stated my outer rims were shot, and I needed two new ones. So that was not something that was great to hear, but as I said, I knew the lack of maintenance, and the fact they were calcium filled, was going to be a problem "one day", well here I am. Honestly, I think even if I had got to replacing the tires and tubes 10 years ago when Dad passed away, the outer rims would still have been non-salvageable, so I would be in the same position I am now, but who really knows.

So, now that I have the tractor on stands with the rear tires off, and the fenders removed, I thought it was time to fix some leaks, and try to fix the 3pt hitch bleeding off with the engine shut down.

Specific leaks:

1. Drivers side 3pt lift arm drips

2.Drivers side load control shaft drips

3.Rear PTO engagement lever drips (next to left heel) Can this be changed now that I have the rock shaft housing removed? Or does the tractor have to be split to get at the seal for this lever?

----------------------------------------------------------------------------------------------------------------

I got my manuals, and started to remove the rock shaft assembly. I was able to remove the rock shaft housing, and started to tear into it.

It was real fun beating the living **** out of one of the 3pt lift arms. One just would not come off the splines, and I ended up breaking it.

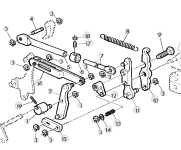

I then removed the 3pt control lever, and drove out the roll pin so I could remove it from the housing. I then removed the cylinder body from the rock shaft housing, set that all aside and went about removing the rock shaft cam and rock shaft from the housing.

Here is where I am at right now, and it doesn't look good.

First, I see a chunk missing from the cylinder wall.

Secondly, I see what looks like wear, or contact on the inner surface of the rock shaft housing? It looks like the cylinder has been over extending maybe, and smashing into the underside of the housing? I don't know, but this definitely doesn't look normal. What would cause this? I have never had a problem using the 3pt other than it would quickly bleed off after shut down?

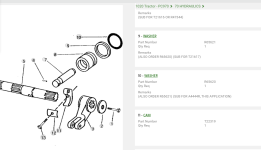

Here are some shots of the piston.

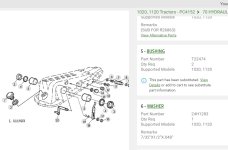

Finally, here is what looks to be one of the brass bushings for the rock shaft. One side it snugly fit into the bore, and this one just falls out with little resistance? What should I do here? Just order a new one?

Sorry for all the questions mixed into the long post, but any guidance would be greatly appreciated!!!:thumbsup:

I hope everyone is staying safe with what is going on these days, etc.

I was recently using the old 1020D to grade the girlfriends driveway, and use it around her place to clear some land, grading work, etc.

I unfortunately blew one of the rear tires, and split the tube....was leaking ballast all the way as I was towing the old girl back home. I knew this day would come when the lack of maintenance in terms of rear tires and rims would no longer "wait", and become a headache. Just wish it happened at home. Oh well.

Got it home, jacked it up, and started to tear into it. I was able to remove both rear rims/tires, and separate the inner rims from the outer rim frame/tire. I loaded the two tires/outer rims onto the trailer to get new tires, tubes, and ballast fill.

Well, got to the tire shop, and they stated my outer rims were shot, and I needed two new ones. So that was not something that was great to hear, but as I said, I knew the lack of maintenance, and the fact they were calcium filled, was going to be a problem "one day", well here I am. Honestly, I think even if I had got to replacing the tires and tubes 10 years ago when Dad passed away, the outer rims would still have been non-salvageable, so I would be in the same position I am now, but who really knows.

So, now that I have the tractor on stands with the rear tires off, and the fenders removed, I thought it was time to fix some leaks, and try to fix the 3pt hitch bleeding off with the engine shut down.

Specific leaks:

1. Drivers side 3pt lift arm drips

2.Drivers side load control shaft drips

3.Rear PTO engagement lever drips (next to left heel) Can this be changed now that I have the rock shaft housing removed? Or does the tractor have to be split to get at the seal for this lever?

----------------------------------------------------------------------------------------------------------------

I got my manuals, and started to remove the rock shaft assembly. I was able to remove the rock shaft housing, and started to tear into it.

It was real fun beating the living **** out of one of the 3pt lift arms. One just would not come off the splines, and I ended up breaking it.

I then removed the 3pt control lever, and drove out the roll pin so I could remove it from the housing. I then removed the cylinder body from the rock shaft housing, set that all aside and went about removing the rock shaft cam and rock shaft from the housing.

Here is where I am at right now, and it doesn't look good.

First, I see a chunk missing from the cylinder wall.

Secondly, I see what looks like wear, or contact on the inner surface of the rock shaft housing? It looks like the cylinder has been over extending maybe, and smashing into the underside of the housing? I don't know, but this definitely doesn't look normal. What would cause this? I have never had a problem using the 3pt other than it would quickly bleed off after shut down?

Here are some shots of the piston.

Finally, here is what looks to be one of the brass bushings for the rock shaft. One side it snugly fit into the bore, and this one just falls out with little resistance? What should I do here? Just order a new one?

Sorry for all the questions mixed into the long post, but any guidance would be greatly appreciated!!!:thumbsup:

Last edited: