Thank you for the replies. I really appreciate your input and knowledge.

Tx. Jim and BukitCase, can you please dumb it all down for me lol? I am lost. Any guess on the weight of a model 47 loader? Or total approximate weight of my 1020D ballasted with the 47 loader?

Thank you for getting back to me Zebrafive. You can click on the images to enlarge them if that provides any clarity at all? With that being said, I will try to explain what I see (please excuse my terminology).

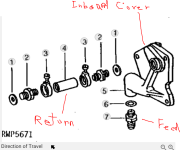

(Working from the FEL control block back)

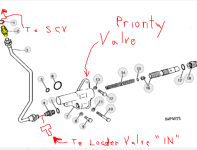

1) Two hoses leave the FEL control block

2) These same two hoses connect or are plumbed directly into the side (outside face) of the SCV block.

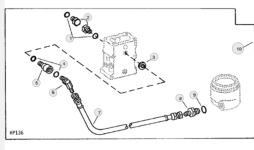

3) Then I see one hard line that exits the bottom front of the SCV block and makes a connection to an area "just behind" my filter cover???

4) The yellow hard line that is shown then runs up to the front of my tractor and connects to my main hydraulic pump.

5) Here is what I believe is my "already" ported filter cover? What line gets connected into that "port", and what are the benefits, etc.? Knowledge please HAHA!!!

Thank you in advance!!!

Tx. Jim and BukitCase, can you please dumb it all down for me lol? I am lost. Any guess on the weight of a model 47 loader? Or total approximate weight of my 1020D ballasted with the 47 loader?

Thank you for getting back to me Zebrafive. You can click on the images to enlarge them if that provides any clarity at all? With that being said, I will try to explain what I see (please excuse my terminology).

(Working from the FEL control block back)

1) Two hoses leave the FEL control block

2) These same two hoses connect or are plumbed directly into the side (outside face) of the SCV block.

3) Then I see one hard line that exits the bottom front of the SCV block and makes a connection to an area "just behind" my filter cover???

4) The yellow hard line that is shown then runs up to the front of my tractor and connects to my main hydraulic pump.

5) Here is what I believe is my "already" ported filter cover? What line gets connected into that "port", and what are the benefits, etc.? Knowledge please HAHA!!!

Thank you in advance!!!