3RRL

Super Member

- Joined

- Oct 20, 2005

- Messages

- 6,931

- Tractor

- 55HP 4WD KAMA 554 and 4 x 4 Jinma 284

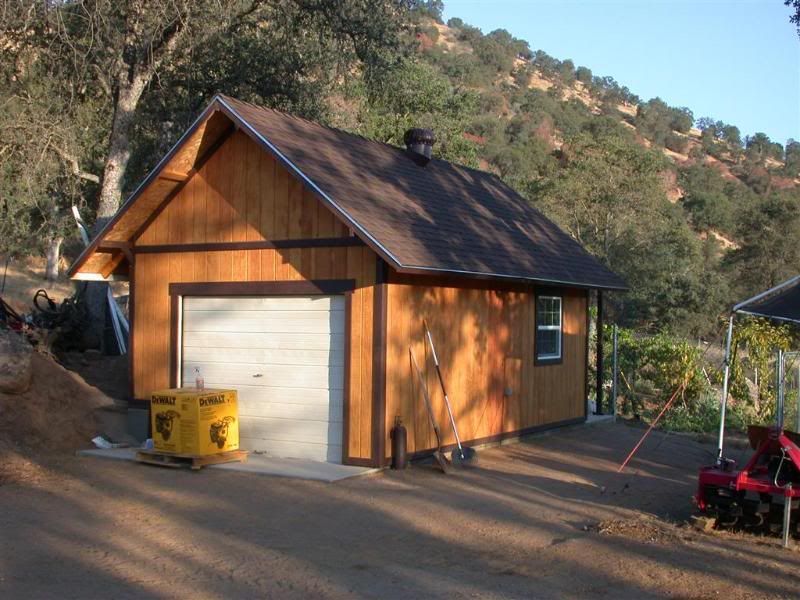

tt - Holy moly haven't heard from you since Oct, Rob. You were already 9 pages back. So more on the shed - please.

OMG. it's been that long already.

Shows you how things pop up around here (to do) and I forget what I'm doing like posting about the garden shed, lol. I think I left off after the slab was cured, right?

BTW, David ... the slab is only 4" thick with wire screen or mesh in it.