Shield Arc

Super Member

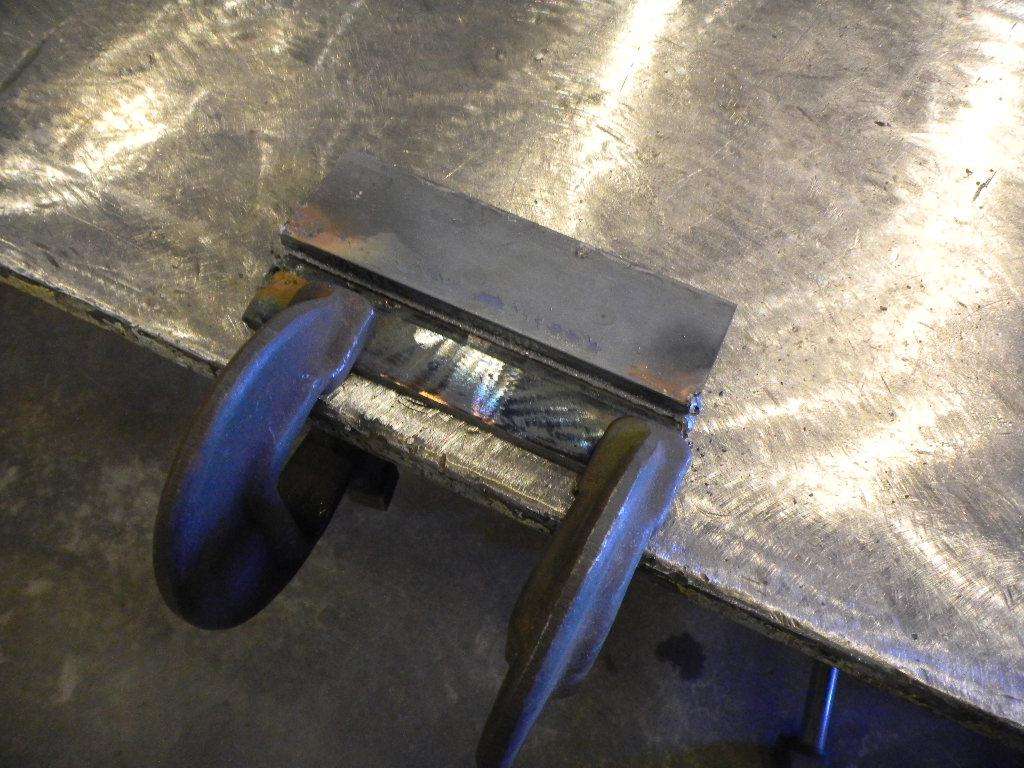

I was asked to do this test on another site, boy this isn't good at all. 1/8-inch 6013, 115-amps, 1/4-inch flatbar. Broke with about three hits of a 4-pound hammer. Then I separated the two pieces by hand!

Couldn't quite get a full 1/4-inch fillet, so it must be about 7/32-inch.

Top plate.

Bottom plate.

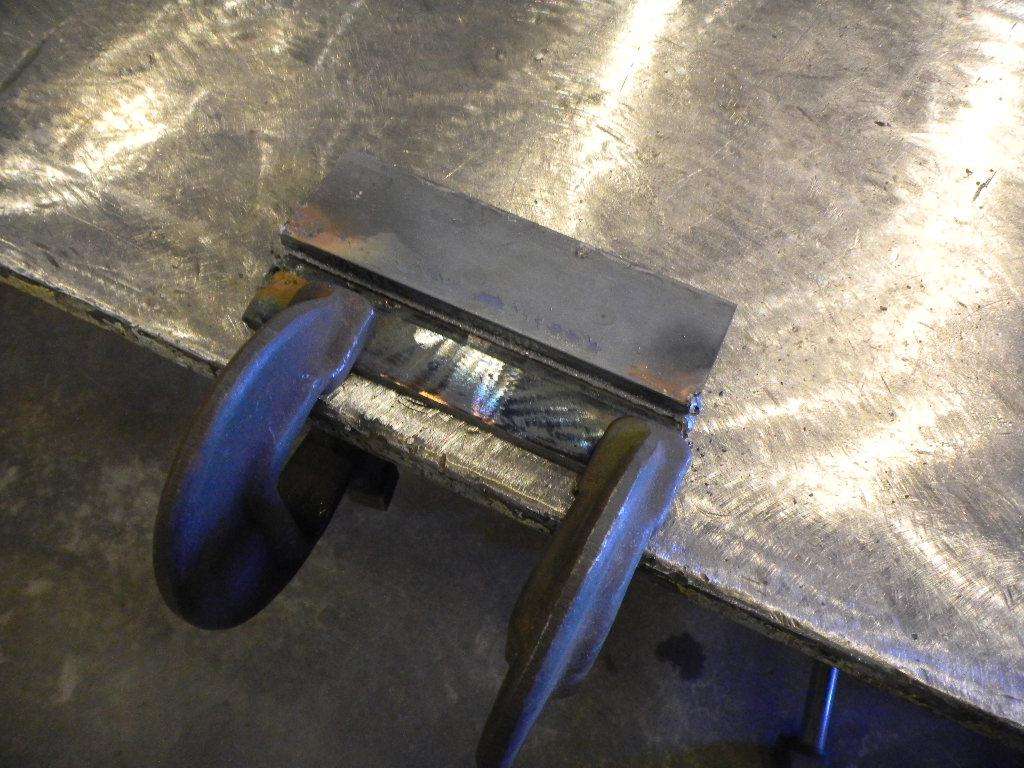

Couldn't quite get a full 1/4-inch fillet, so it must be about 7/32-inch.

Top plate.

Bottom plate.