3RRL

Super Member

- Joined

- Oct 20, 2005

- Messages

- 6,931

- Tractor

- 55HP 4WD KAMA 554 and 4 x 4 Jinma 284

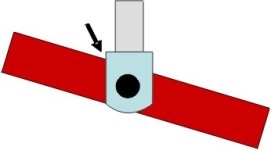

I needed them because I was not sure how it was going to turn out. Especially mounting...hard plumbing the double pilot operated check valves I bought from Surplus Center. I had machined some various nipple lengths in order to get the spacing correct for the hard plumbing. After trying it several times, I finally got the right combination and made a good plumbing job of it. I used pipe joint compound for the NPT fittings. The others were SAE and JIC fittings.

Here's what the cylinder looks like with the check valve mounted. It was a lot harder than I thought but came out just fine. One thing for sure, the Surplus Center DPOCV is a lot bigger than the CCM one on my top link cylinder.

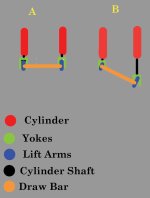

Then I took the cylinder assembly and mounted it to the tractor. I had previously re-attached the top lift arms and lower drag links to be certain I had them in the correct position. The top lift arms are splined so you can set on the tractor at different positions. So I had to check the full movement of the arms to see if there would be any binding or interference. I also checked the to see where the full length and shortened length of the cylinder would position the lower drag arms.

Anyway, this is how the cylinder looks when in position.

Here's what the cylinder looks like with the check valve mounted. It was a lot harder than I thought but came out just fine. One thing for sure, the Surplus Center DPOCV is a lot bigger than the CCM one on my top link cylinder.

Then I took the cylinder assembly and mounted it to the tractor. I had previously re-attached the top lift arms and lower drag links to be certain I had them in the correct position. The top lift arms are splined so you can set on the tractor at different positions. So I had to check the full movement of the arms to see if there would be any binding or interference. I also checked the to see where the full length and shortened length of the cylinder would position the lower drag arms.

Anyway, this is how the cylinder looks when in position.