sixdogs

Super Star Member

- Joined

- Dec 8, 2007

- Messages

- 15,729

- Location

- Ohio

- Tractor

- Kubota M7040, Kubota MX5100, Deere 790 TLB, Farmall Super C

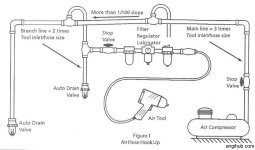

I used to have air lines run in my shop because I painted and needed the moisture removed. At the compressor I had a flex line to a vertical line that crossed over and dropped down to my moisture filter for painting. It looked something like this

It worked great but I just finished insulating my barn and had to take the lines down. I don't paint as much and don't want to run lines again. I have a two stage 100 gallon 180? psi compressor.

Can I just run a short rubber hose off the tank to a moisture filter, possibly right on the tank, and then run my air hose off of that? This would keep it easy for me and I only paint again equipment no that isn't very fussy. I mostly pump up tires.

I'd like to keep it simple. What do others do and how do you run your lines off the compressor to remove moisture?

It worked great but I just finished insulating my barn and had to take the lines down. I don't paint as much and don't want to run lines again. I have a two stage 100 gallon 180? psi compressor.

Can I just run a short rubber hose off the tank to a moisture filter, possibly right on the tank, and then run my air hose off of that? This would keep it easy for me and I only paint again equipment no that isn't very fussy. I mostly pump up tires.

I'd like to keep it simple. What do others do and how do you run your lines off the compressor to remove moisture?