muddstopper

Veteran Member

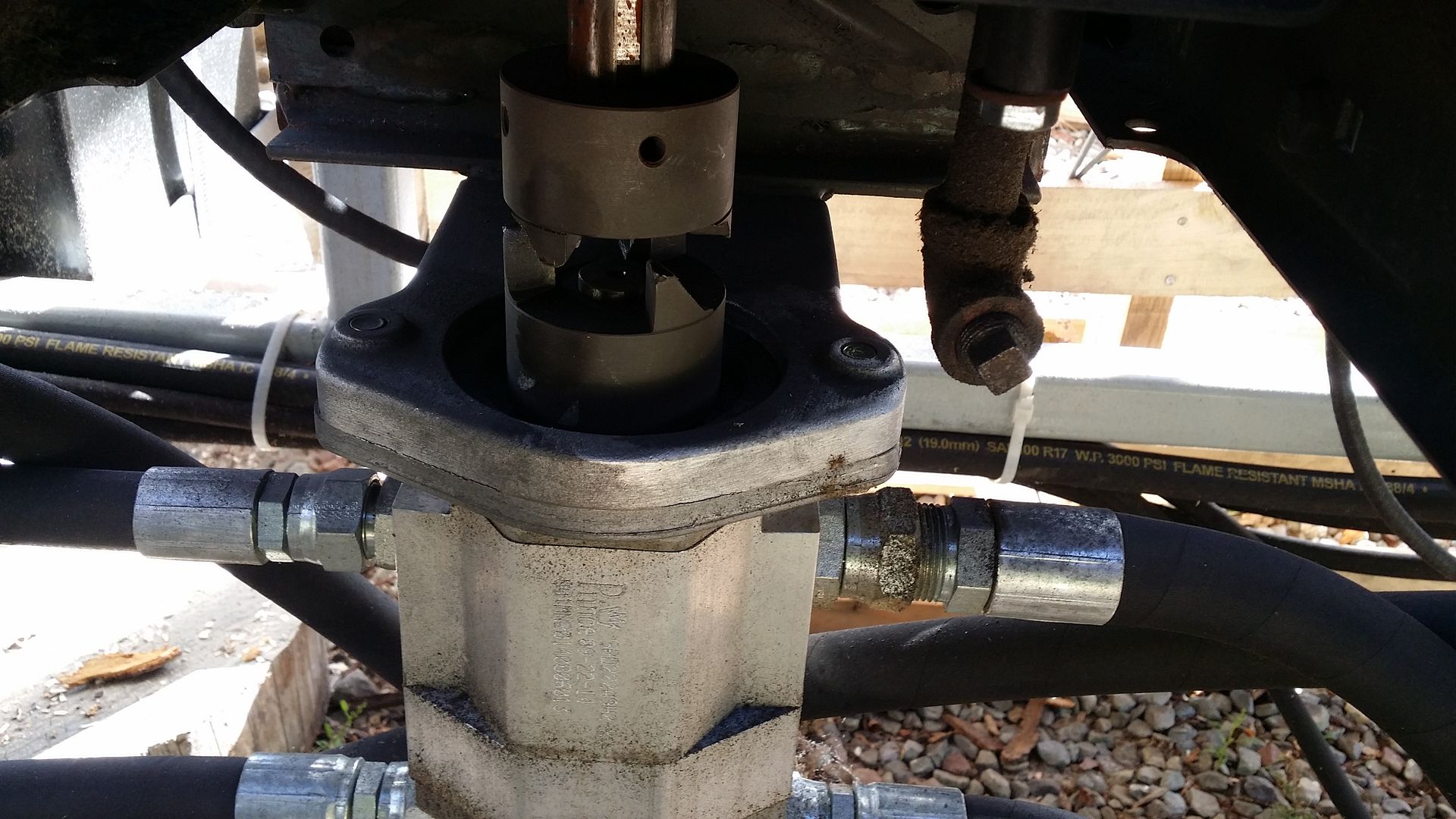

Ill throw up a pic of my cyl mounts.

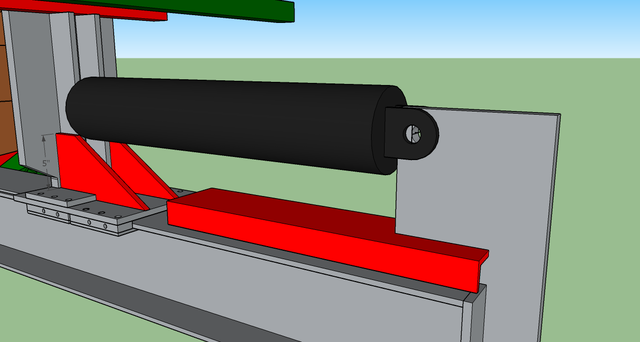

. Of course my mounts are for 2 cyl instead of one, but my pusher block is the same 20in tall as yours. Past experiences on a few other splitter builds and I found pretty much the same thing you have with high cyl mounts. The higher you mount the cyl, the more the base mount is going to flex. While my top cyl is mounted at about the same height as your single cyl, I mounted the bottom cyl as close to the hbeam as possible. I also chose to use to side plates for the base instead of one center mount which will give a little more support when pushing. I havent boxed my beam yet, but your pic's of boxing the beam is pretty much exactly what I had planned. I also intend to plate the top of my beam. Plating the top of the beam will provide a lot of support when it comes to bending/flexing the hbeam under load. My thought for you are to lower your cyl mounts as low as possible. Make your slide/pusher plate as long as possible and then brace the pusher to keep it from bending backwards. My current splitter has a 5in bore cyl and is mounted with a single 1 in plate at the base like yours, and the sides of the web are plated with additional 3/4 plate, both sidesbut it only extends about 6 or 8 inches toward the front of the hbeam. I have never noticed my hbeam flexing at the base of the cyl. The wedge end of my beam is plated on both side with 3/4 plate and 6in channel on both side.

. Of course my mounts are for 2 cyl instead of one, but my pusher block is the same 20in tall as yours. Past experiences on a few other splitter builds and I found pretty much the same thing you have with high cyl mounts. The higher you mount the cyl, the more the base mount is going to flex. While my top cyl is mounted at about the same height as your single cyl, I mounted the bottom cyl as close to the hbeam as possible. I also chose to use to side plates for the base instead of one center mount which will give a little more support when pushing. I havent boxed my beam yet, but your pic's of boxing the beam is pretty much exactly what I had planned. I also intend to plate the top of my beam. Plating the top of the beam will provide a lot of support when it comes to bending/flexing the hbeam under load. My thought for you are to lower your cyl mounts as low as possible. Make your slide/pusher plate as long as possible and then brace the pusher to keep it from bending backwards. My current splitter has a 5in bore cyl and is mounted with a single 1 in plate at the base like yours, and the sides of the web are plated with additional 3/4 plate, both sidesbut it only extends about 6 or 8 inches toward the front of the hbeam. I have never noticed my hbeam flexing at the base of the cyl. The wedge end of my beam is plated on both side with 3/4 plate and 6in channel on both side.  , I have seen it flex and I actually think I bent the hbeam where the plateing ends. My wedge is 24in tall adjustable and a 6way. If your not able to lower the cyl mounts, you might consider just welding ome sqtube between the cyl and beam. You can sandwich the base mount between the tube to give it some extra support at the same time. probably the cheapest, easiest fix and will really give your hbeam a boost of strength

, I have seen it flex and I actually think I bent the hbeam where the plateing ends. My wedge is 24in tall adjustable and a 6way. If your not able to lower the cyl mounts, you might consider just welding ome sqtube between the cyl and beam. You can sandwich the base mount between the tube to give it some extra support at the same time. probably the cheapest, easiest fix and will really give your hbeam a boost of strength

I think the URL is a little off, Your not a dumbass, dumbasses dont build what you have built.

. Of course my mounts are for 2 cyl instead of one, but my pusher block is the same 20in tall as yours. Past experiences on a few other splitter builds and I found pretty much the same thing you have with high cyl mounts. The higher you mount the cyl, the more the base mount is going to flex. While my top cyl is mounted at about the same height as your single cyl, I mounted the bottom cyl as close to the hbeam as possible. I also chose to use to side plates for the base instead of one center mount which will give a little more support when pushing. I havent boxed my beam yet, but your pic's of boxing the beam is pretty much exactly what I had planned. I also intend to plate the top of my beam. Plating the top of the beam will provide a lot of support when it comes to bending/flexing the hbeam under load. My thought for you are to lower your cyl mounts as low as possible. Make your slide/pusher plate as long as possible and then brace the pusher to keep it from bending backwards. My current splitter has a 5in bore cyl and is mounted with a single 1 in plate at the base like yours, and the sides of the web are plated with additional 3/4 plate, both sidesbut it only extends about 6 or 8 inches toward the front of the hbeam. I have never noticed my hbeam flexing at the base of the cyl. The wedge end of my beam is plated on both side with 3/4 plate and 6in channel on both side.

. Of course my mounts are for 2 cyl instead of one, but my pusher block is the same 20in tall as yours. Past experiences on a few other splitter builds and I found pretty much the same thing you have with high cyl mounts. The higher you mount the cyl, the more the base mount is going to flex. While my top cyl is mounted at about the same height as your single cyl, I mounted the bottom cyl as close to the hbeam as possible. I also chose to use to side plates for the base instead of one center mount which will give a little more support when pushing. I havent boxed my beam yet, but your pic's of boxing the beam is pretty much exactly what I had planned. I also intend to plate the top of my beam. Plating the top of the beam will provide a lot of support when it comes to bending/flexing the hbeam under load. My thought for you are to lower your cyl mounts as low as possible. Make your slide/pusher plate as long as possible and then brace the pusher to keep it from bending backwards. My current splitter has a 5in bore cyl and is mounted with a single 1 in plate at the base like yours, and the sides of the web are plated with additional 3/4 plate, both sidesbut it only extends about 6 or 8 inches toward the front of the hbeam. I have never noticed my hbeam flexing at the base of the cyl. The wedge end of my beam is plated on both side with 3/4 plate and 6in channel on both side.  , I have seen it flex and I actually think I bent the hbeam where the plateing ends. My wedge is 24in tall adjustable and a 6way. If your not able to lower the cyl mounts, you might consider just welding ome sqtube between the cyl and beam. You can sandwich the base mount between the tube to give it some extra support at the same time. probably the cheapest, easiest fix and will really give your hbeam a boost of strength

, I have seen it flex and I actually think I bent the hbeam where the plateing ends. My wedge is 24in tall adjustable and a 6way. If your not able to lower the cyl mounts, you might consider just welding ome sqtube between the cyl and beam. You can sandwich the base mount between the tube to give it some extra support at the same time. probably the cheapest, easiest fix and will really give your hbeam a boost of strengthI think the URL is a little off, Your not a dumbass, dumbasses dont build what you have built.

![IMG_20150217_220514[1].jpg IMG_20150217_220514[1].jpg](https://www.tractorbynet.com/forums/data/attachments/377/377131-4a40b1ccdcf41dc0ed23e114a6152212.jpg)