Ok, then doesn't it make more sense to get some 3ph implements? You need them right eventually, right?

Time, money and effort just to build single-use and otherwise useles item could be spent buying something that is actually useful.

I am not sure what 3ph implement I might want. I am not farming. The tractor is on a 'weekender' property. The property is VERY hilly, with steep roads (not just a nice, level, gravel driveway). No grass - just thousands of trees.

To date the tractor has been used mainly for moving stuff around using the forks, a bit of moving stuff around with the bucket, and using the bucket to improve the really bad patches of road. The bucket is not the ideal tool for the job, but I am struggling to find out which implement would be best.

The roads are unpaved and full of lots of small stones, up to about 4-5" diameter. I have had different 'experts' suggesting grader-scrapers, box scrapers and land planes.

Ideally, I would like to hire an implement or two to 'experiment' with. Unfortunately, I can't find anyone who hires out these sorts of farm implements. I'd be happy to buy some second-hand implements, but it seems that Aussie farmers never sell them. New implements range from about $1.5K to $3K. That's not the sort of money I can afford to spend on the wrong implement.

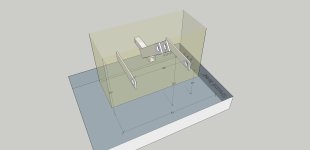

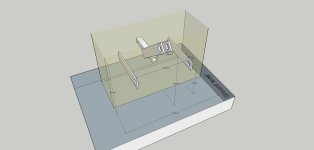

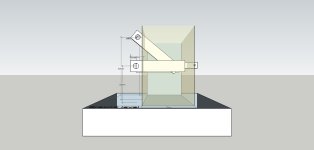

My ballast barrel won't cost me that much. About $50 for the steel to make the hitch, $0 for the barrel, $0 for the steel for the ballast (primarily using scrap brake disks, and any other bits of scrap I can lay my hands on). I'll use concrete to fill in all the voids between the steel bits, which hopefully won't amount to many dollars.