s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,607

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

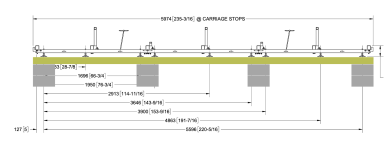

So I have a Woodland Mills HM122 on the way, should be here next week. It comes with leveling feet but will be down on the ground if I don't build a base. The only other mills I have used a lot were trailer-mounted and the deck was up near knee height. I am thinking I should build a base to elevate this new mill to minimize back strain.

Has anybody build a base for a mill before and care to offer suggestions or photos? I think my options are concrete blocks or pressure-treated timbers. Blocks are cheap, about $1.60 each for an 8x8x16. And concrete is still around $3.50-$4 a bag. Lumber, on the other hand -- I'd be paying $21 for an 8' 4x6 pressure-treated timber, which is a ripoff. I'd need about 10 of them, to the tune of $210. That is too darn expensive/ironic considering I bought the mill to avoid overpaying for lumber.

I could do the same thing with concrete block by building up piers. It would be slower to build. But I'd only need about $50 worth of blocks then another $20 for mortar etc.

Any other ideas?

thanks,

219

Has anybody build a base for a mill before and care to offer suggestions or photos? I think my options are concrete blocks or pressure-treated timbers. Blocks are cheap, about $1.60 each for an 8x8x16. And concrete is still around $3.50-$4 a bag. Lumber, on the other hand -- I'd be paying $21 for an 8' 4x6 pressure-treated timber, which is a ripoff. I'd need about 10 of them, to the tune of $210. That is too darn expensive/ironic considering I bought the mill to avoid overpaying for lumber.

I could do the same thing with concrete block by building up piers. It would be slower to build. But I'd only need about $50 worth of blocks then another $20 for mortar etc.

Any other ideas?

thanks,

219