OP

muddstopper

Veteran Member

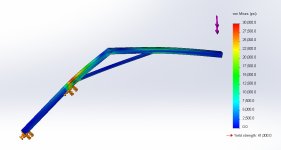

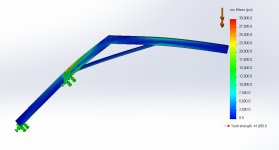

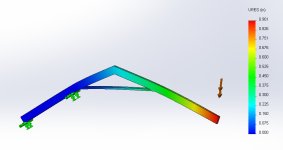

My 1960'sRyerson steel data book says 4x4-1/4" weight/foot 12.51 and will take 14.5 kips @ 6'

10x2-3/16" is a pound heavier @14.65#/foot but will take 27.4 Kips.

Go skinny and deep may help with visibility and Welding the ends?

I dont think I want to go skinny simply because the sideways flex, especially if I bump something, might be more than the boom can take. I took a good look at the 4x4 tube I was planning on using, it seems it already has a pretty good bow in it. Most likely, I will endup buying new steel for the boom. The hub I am using as a base is 8.5in in dia, so thats what the inside distance will between the uprights for the boom/cyl mounts. I think 5 inch tube will be what I go with. I have thought about using 2x4 tube and doubling the tubes.