Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,311

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

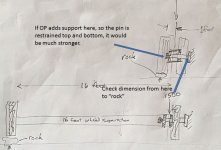

JB, I think that 24,000 lb rated hub might be "right in the hunt" for this project. Plus it's built to take a cyclic load for tens of thousands of miles, with a significant safety factor (DOT approval).

This log loader's gonna cook Mudd out of his house before it even scrounged a hundred 2000 lb logs at 16ft extension, I don't see the cycles adding up to anything significant.

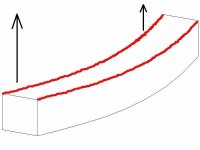

Truck hub widened to 16 feet and runs over a rock, lifting inside tire off the ground. 1500 lbs at 16 feet creates the same moment on the axle stub as 24,000 lbs on just one wheel. 1500 x 16ft = 24,000 x 1ft

The FBD is not really correct, it's a simplification. The load actually comes in where the hub is affixed thus it can support MORE than 1500 lbs at 16 feet. This is just to make the point is I think that hub is OK. Can you look at my assumptions and give your opinion?

This log loader's gonna cook Mudd out of his house before it even scrounged a hundred 2000 lb logs at 16ft extension, I don't see the cycles adding up to anything significant.

Truck hub widened to 16 feet and runs over a rock, lifting inside tire off the ground. 1500 lbs at 16 feet creates the same moment on the axle stub as 24,000 lbs on just one wheel. 1500 x 16ft = 24,000 x 1ft

The FBD is not really correct, it's a simplification. The load actually comes in where the hub is affixed thus it can support MORE than 1500 lbs at 16 feet. This is just to make the point is I think that hub is OK. Can you look at my assumptions and give your opinion?

Attachments

Last edited: