the old grind

Elite Member

- Joined

- Jul 21, 2012

- Messages

- 4,412

- Location

- Mid-Michigan

- Tractor

- NH T-1520 HST, NH TC33DA HST, Case DX26 HST, .Terramite T5C, . NH L785

Re: Big Barn痴 Retirement Farm Shop

Gale, why don't I just leave the rotab on there when I bring my mill to trade for yours. :laughing: (You'd want to keep your DROs.)

I have a walkout downstairs and use the Terramite's stinger to fit machines through the sliding door. I suggest you tote the mill by removing the head at the column riser, splitting the weight nearly in half and where there's no tech to r & r the bits. (4 bolts) I doubt if either piece weighs nearly what it looks like, or half a thou'. You don't want it to travel upright and in one piece, anyway. I don't ever have the luxury of a helper when moving machines or safes, but always manage.

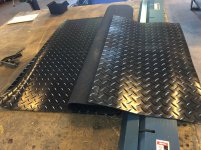

Use a few extra ratchet straps, an appliance dolly, and two college hunks if you have to go up stairs with the halves. I do use a 1-T HFT shop crane indoors vs tractors out, and I might have set the head back on by hoisting from the ceiling and rolling the base under it. (Big 'dowels' are still under it and it pulls out nicely to sweep/vac chips.) This pic is from when setting the 12" x 36" lathe (2010?). Lionel (TM) has since cost me ~1/3 of the room, so the small mill is tuck in by the near end of the lathe. Table at right is behind the G-9972Z, which never sat to a wall and does most turning work despite being 'plastic-rated' (my words).

Y'now ... I don't need the Palmgren rotab (have the box, too) nearly as much as I wish I had a column riser for my 12" x 28" Enco mill .....

Gale, why don't I just leave the rotab on there when I bring my mill to trade for yours. :laughing: (You'd want to keep your DROs.)

I have a walkout downstairs and use the Terramite's stinger to fit machines through the sliding door. I suggest you tote the mill by removing the head at the column riser, splitting the weight nearly in half and where there's no tech to r & r the bits. (4 bolts) I doubt if either piece weighs nearly what it looks like, or half a thou'. You don't want it to travel upright and in one piece, anyway. I don't ever have the luxury of a helper when moving machines or safes, but always manage.

Use a few extra ratchet straps, an appliance dolly, and two college hunks if you have to go up stairs with the halves. I do use a 1-T HFT shop crane indoors vs tractors out, and I might have set the head back on by hoisting from the ceiling and rolling the base under it. (Big 'dowels' are still under it and it pulls out nicely to sweep/vac chips.) This pic is from when setting the 12" x 36" lathe (2010?). Lionel (TM) has since cost me ~1/3 of the room, so the small mill is tuck in by the near end of the lathe. Table at right is behind the G-9972Z, which never sat to a wall and does most turning work despite being 'plastic-rated' (my words).

Y'now ... I don't need the Palmgren rotab (have the box, too) nearly as much as I wish I had a column riser for my 12" x 28" Enco mill .....