Bob,

I think the main point of this thread is getting lost in the analysis of forces. Just to be clear the meaning of breakout force, as applied to agricultural FELs, is defined in the paragraphs 5.1.5 and 5.1.6 of ASAE 301.3. The rest of this discussion is getting into an analysis of the forces involved.

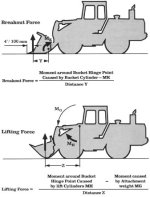

I'll try to address your response without getting too wordy. <font color="blue"> Yes, it is directed upwards but is also directed back as well as part of the calculation includes subtracting the distance of travel around the pivot point. </font> If you examine the drawing Boomerang1 provided you'll see arrows indicating the direction of forces. Notice the circular arrow at the bucket pins labeled MK, which is showing a clockwise twist around the pivot point. Notice the arrow labeled breakout force points straight up and the label Y is signifying distance not a force. The equation below the picture defined MK to be the moment around the bucket hinge point. If you check a good dictionary or a physics text you find that the word moment and torque closely related and are often used synonymously (

Torque/Moment offers a nice explaination). It’s a good drawing showing how the defined forces are interacting, but its saying nothing about bucket curl being a component of breakout force.

<font color="blue"> You state </font> <font color="green"> If numbers for both 5.1.5 and 5.1.6 is reported you can calculate the rollback force (torque) the loader can assert. </font> <font color="blue"> And while it has been 20+ years since I had freshman physics, I don't see how that can be true unless you assume that the curl cylinders have the same capacities as the lift cylinders</font> Its been more then 20 years for me too. We can determine the rollback because 5.1.5 is the lifting force at the pins, since pins are the point the bucket rotates around the distance is zero. Torque is defined as the rotational force time the distance from the rotation point we know torque is zero (Anything * 0 = 0). The next part is 5.1.6 requires the bucket to remain parallel to the ground, and we know the lifting cylinders are the same. Therefore the difference between 5.1.5 and 5.1.6 is how much force the rollback cylinders can apply to resist the downward twisting force (torque) of the load. The last part is the fact the standard defines the distance (500mm CUTs, 800mm UTs) the force is applied at for the test. Keeping that in mind the equation for the rollback force the loader can assert is:

Rollback Force = (5.1.5 Breakout force - 5.1.6 Breakout force) / by 500 (or 800) mm

I am making the assumption that the FEL doesn’t use rollback cylinders so large that 5.1.6 equals 5.1.6. It would be possible to do so, and very useful for using pallet forks, but I haven’t seen any CUT FEL that does.

<font color="blue"> I just don't see the same measurements being used in the ASAE CUT/UT specs and those in the diagram provided by Boomerang1. </font> I agree this diagram doesn’t depict any measurements, only direction of forces. Its important to remember this diagram isn’t a standard; it’s a depiction of the forces involved. Sorry for being so long winded folks.