SPYDERLK

Super Star Member

- Joined

- Feb 28, 2006

- Messages

- 12,530

- Location

- VA

- Tractor

- JD2010, Kubota3450,2550, Mahindra 7520 w FEL w Skid Steer QC w/Tilt Tatch, & BH, BX1500

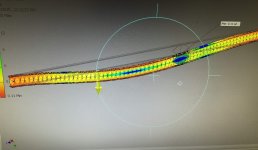

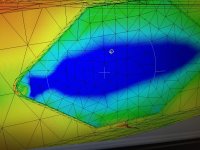

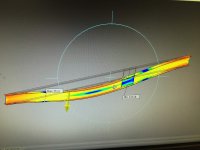

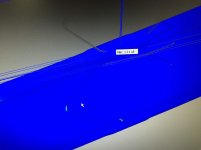

The beauty of bolting is that its something anyone can do. No special tools or skills required. IOW, very little control needed for a serviceable job ... except maybe tighten the bolts again after initial [fast] tensile creep.Yeah I'm going to disagree with you on that! Have you run FEA on both design to look at stress concentrations?

Also bolting is a more controlled solution to splice two beams together. Done all the time in I-beam structures. Multiple bolt holes distribute stress loads and friction force holds everything together.