Just2quickz28

Gold Member

SkunkWerX said:i hate to fabricate a Quick Attach and find it weighs 100#, that is 1/5th of the bucket lift capacity robbed.

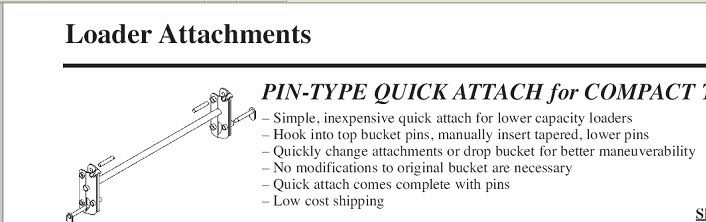

Exactly, for what I am looking for that ATI Pin on looks decent enough. If you look closely at the the ATI PIN On QA the ends where it will meet the bucket are tapered almost triangular to help with lining up the attachments. And then for building attachments use the bucket mounts as a template and go to town. I am going to stop at the local dealer on my way home from work and see what they say.