beowulf

Veteran Member

- Joined

- Dec 31, 2003

- Messages

- 1,316

- Location

- Central California Foothills

- Tractor

- Kubota L3410 HST, J Deere riding mower

I need a cattle guard for a new access road to the property. They can be bought, but those online are expensive and present an issue re unloading. E.G., One that I found online weighs 1791 lbs and the seller states the buyer is responsible for unloading it when it is delivered. I have a Kubota L3410 with a Woods 1016 FEL, and the manual states it's capacity is 1600 lbs. I don't want to have issues if I get this when it is delivered. Also very expensive - over $3,200.

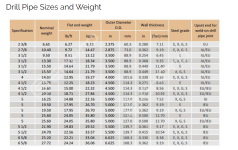

I have a source for used oil rig pipe (3 1/2 dia, 31 foot lengths for $85 each, plus $2.50 for any cuts). I have used that pipe for gate posts and it is really heavy. Anyway, I am thinking I can get some large angle iron and have some one weld it all together on site. The two cattle guards that were here when we bought 35 years ago are made precisely like that - pipe and angle iron. I could then make a structure for them to sit on /fit into, with drainage etc.. I would pour a concrete perimeter and one or two cross beams. Likely 8' x 12' overall.

Your thoughts? Your experiences? Thanks in advance.

I have a source for used oil rig pipe (3 1/2 dia, 31 foot lengths for $85 each, plus $2.50 for any cuts). I have used that pipe for gate posts and it is really heavy. Anyway, I am thinking I can get some large angle iron and have some one weld it all together on site. The two cattle guards that were here when we bought 35 years ago are made precisely like that - pipe and angle iron. I could then make a structure for them to sit on /fit into, with drainage etc.. I would pour a concrete perimeter and one or two cross beams. Likely 8' x 12' overall.

Your thoughts? Your experiences? Thanks in advance.