bmac

Veteran Member

EddieWalker said:bmac,

The proper way is to run an stud on edge from the second rafter in so that it rests on the top of the outside rafter. This means cuttind down the outside rafter or notching it. This is code, and the strongest way to get a one foot or longer overhang.

Have fun,

Eddie

OK, Eddie. The above quote is from an earlier reply about framing out the gable end of the roof. Although it was too late to work on the coop when I got home this evening, I thought I'd make a test run of what I think you meant on some scrap wood.

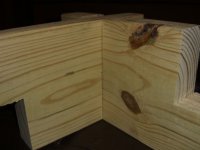

The first photo shows the notches (the first set was too deep so I made an adjustment and cut another set).

The second set shows the assembled product. The edges actually are flush despite the appearance of the photo.

I asked the guy at the lumber yard what he'd recommend for fascia and soffitt. His reply was HardiPlank so that's what I bought. I think I should have researched this before buying. Had I done my research first, I would have known that the Hardie fascia requires a solid wood "subfascia" Which means I have to put up 2x6's on the rafter ends before I put up the Hardie fascia. I'm committed to this now as I've shortened the rafters enough to account for the extra thickness. It also now means that I'll have to shorten each end of my ridge board 1 1/2 inches. I can do this with a hand saw or a circular saw - either way I'm doing it while atop a tall ladder - not something I'm looking forward to.

As far as the Hardie soffit material, I think I'll be forced to install it horizontally and add some 2x4 framing from the walls to the ends of the rafters along with a nailer board running the length of the 2 side walls. Essentially, a conventional houe soffitt. With the 2x6's added to the ends of the rafters, I don't think I'll be able to fasten the soffit material to the underside of the rafters as there will be a large gap between the soffitt and the 2x6 subfascia. Am I making sense?

Oh well, I'm learning from my mistakes.