Yeah, metal fab -it's a pretty good hobby to get into. Some times it goes over the top. But I will tell you, working square tubing with decent cuts and a little bit of knowledge and practice is a beautiful thing. You could spend your cash on worse things. Your thoughts on a bandsaw, if your good taking your time, probably have a home shop so it will be quieter and more civilized. Set up your weld table. It will be great. Don't pay us old farts any mind at all. (removed) makes some good points that really you don't here anymore. We're in a society of deposable income, but it wasn't always that way and probably we'll see those times again.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chop Saw Reccomendations

- Thread starter JohnnyMX

- Start date

- Views: 20015

More options

Who Replied?

/ Chop Saw Reccomendations

#61

WranglerX

Super Member

Actually I have a abrasive chop saw and a horizontal band saw.... The band saw is a Craftsman Professional, it actual cuts on left side where as most saws cut on right side.... Fellow I got it from for ragingly large amount of $20 said it "did not cut".... Got it home plugged it in, motor would not spin up, after clean about 5 pounds of "mud dobber" nest out of motor it ran fine... Looked at blade, teeth are running "backwards" ????... Have to turn a standard blade inside out to get teeth to run in correct direction.... Cuts fine....Eventually had to replace "rubber bands" (tires) and a bevel gear but still into it about 1/3 of what cheapest new costs.... Its my go to for more precision or long duration cuts as I can set it up start it up and walk away and it just does its thing....

Not mine, but identical to mine....

Dale

Not mine, but identical to mine....

Dale

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 7,047

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

^^ If you read saw reviews, but more often the blade reviews, there is an occasional '1 star' rating because "the blade was build backwards and the teeth are going in the wrong direction".

^^^ Very true. I have a bunch of them.

user.69169

Veteran Member

- Joined

- Feb 22, 2009

- Messages

- 1,346

Average clown on couldesac just run longer and let blade rub thru. Probably got no idea blade is directional. Look at most hand hacksaws, 3" of blade wore out, rest still got factory paint on de teeth. Supposed to be dat way, don't it look good hanging on pegboard wall? Even spent time to shadow paint all his tools. Man gets paycheck for sitting in little cube and has time to moderate internet board from his device at work too. Spent a lot of time in school stuffed in hall locker when he was Hall Monitor. Switched to dat job from Crossing Guard after girls hooked his belt to flagpole rope & hauled him up.

crazyal

Super Member

Probably the same crowd that finds half the nails have the points on the wrong end when they take them out of the box.

user.69169

Veteran Member

- Joined

- Feb 22, 2009

- Messages

- 1,346

Probably the same crowd that finds half the nails have the points on the wrong end when they take them out of the box.

I given up tellin dem guys dey sposta set dem nails aside cause dey fer other side of building.

Used to be "home center" here dat catered to large collection of medical doctors on Saturday morning. OK, dese are educated men, possibly some benefit to world, altho some I wondered about. Dozen or so of dem sitting on little bleacher contraption watchin demonstration of sanding floor wid rental machine.

(removed) bein de man he is gotta participate. I feel I belong, dey all got equipment hats so I fit right in wearin genuine Ancorage CAT hat.

Barely got comfortable when man offers to buy my hat for $50- Nope, cold outside (removed) needs hat.

Instructor fellow talkin about paper to strip old finish. I ask why not just throw sand and water on floor and use Skotchbrite. How de he!! I know profit to store in selling paper?

Nother doctor offers 75 for my hat. Nope, got it as christmas gift, Auction went to $150 and (removed) walked out werin de hat. Emailed my bud in Ak see can he get more.

Best part was doc who stood der runnin sander while instructor answered questions.. Machine sure was loud when it got thru fake floor and fell onto concrete floor.

UPDATE: After going through all the comments on here and assessing my holiday gift card situation, I ended up getting the HF horizontal bandsaw. I also took some of the price difference between a dry cut chop saw and this option to get a couple of Fireball Tool minion squares. For the saw and a couple of their cheap blades, I spent about 250 in total. Contrary to most of the reviews online, the setup was pretty easy, and my saw ran great out of the box. A couple of quick tweaks and it was cutting perfect 90s with no vibrations, squealing, etc. The saw cuts almost silently (no ear protection needed), is fast through mild steel, and leaves very little mess to be cleaned up. The cuts were also clean enough that I didn't need to do much clean-up before welding. The footprint is also reasonable and the saw wheels out of the way. The cart it comes with does give me some reservations, but it is functional for now.

I am doing all my work on a cheap HF portable welding table and my concrete floor for now, so this combo really stepped up my game on my first project.

I am doing all my work on a cheap HF portable welding table and my concrete floor for now, so this combo really stepped up my game on my first project.

Glad to hear you found a solution that works for you. I had my HF saw cutting steel yesterday, and it continues to impress me with it's accurate and clean cuts. I get a smile on my face every time I see it running almost silently.

sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 6,340

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

Excellent discussion, and like most metal working and wood working projects there is more than one way to skin a cat.

My tool collection includes the usual right angle grinders, abrasive cut iff saw, acetylene torch, and the crown jewel of metal cutting, a 1940s vintage Kalamazoo 8肺 16 horizontal bandsaw.

Not to hijack this thread but has anyone invested in a plasma cutter and after using it regretted the decision?

Aside from using a cutting torch, my options for cutting steel plate are limited and for several months have been looking at plasma and the Hypertherm XP45 is to die for but a huge dent in the pocket book. Ideally I would like the capacity to cut 1/2 plate but in reality, 1/4 to 3/8 thick would be 99% of my cutting needs.

Any suggestions?

B. John

The china units are getting better a quote from WW member (Brand X)

Fine tuned my $92.00 120 volt plasma. The IGBT in these little units do a good job in them.. 1000 times better than a older mosfet unit,, Key is buying the correct/decent consumables for the torch..

Here are some cuts on a good 20 amp breaker(pulls more amps) 1/2 down to 10 ga..

https://weldingweb.com/vbb/attachment.php?attachmentid=1721621&stc=1&d=1608860812

How cheap can you go?? - Page 3

post 62- Pretty amazing 1/2 cut quality for what the machine cost.

post 64 how he achieved those quality cuts with a sub $100 plasma cutter Swirl ring seems to be a key item.

Another quote:

Cheap China stuff, but I've always had the best luck here..A few things that matter.. Correct .039 nozzles/electrodes, and most important thing is the swirl rings. Most China made ones are drilled at random. If you put ones that spin the air correctly, it will make a huge difference when using the .039 nozzles (30 amp nozzles/ 70 psi flowing) Really the 1/4 inch cut quality/speed is much improved, and overall sever is too.. The life on these consumables is very good too.. This machine blows away the performance of the original Esab Handy Plasma 250 (120 volt only 18 amp machine) imported from Italy years ago.. Herocut is made by Arc Sonic, and has stepped up the low cost Plasma machines.The pierce is really good too.. Punching throw .250 really fast. That was with the older non upgraded consumables. Bet it does 3/8 without issues now. Another test though.

His 1/2 " cuts are better than with my 50 amp MOSFET on 240 VAC

What I have and use use- Rage chop saw for most tubing that i need a clean cut and the abrasive when it isn't as critical

long cuts time for the plasma cutter or the Oxy acet.

Overall Very happy with my 5 year old 3 in 1 50 amp (Arcsonic-Lotos) pilot arc plasma cutter, HF 14 " cut off saw and the Rage saw

the horizontal band saw is still on the wish list

ps. For what brand X paid for his plasma ($91) Can No longer see a Good reason for most not to give an inexpensive Plasma cutter a try, it is now a very,very affordable option.

That is if he isn't pulling our legs. trying to verify the cuts were made by a dirt cheap plasma cutter.

Last edited:

jaxs

Elite Member

Shop fans are hazardous when welding. The increased oxygen excelerate's flames when clothes and nearby combustiables are set on fire.If doing any substantial amount, I set up a shop fan to blow the smoke and fumes away.

That's pretty much my stratagy. Health experts claim fumes from modern synthetics are hard on the lungs so I hold my breath until I can put the fire out. Didn't take long to realize welding nude isn't the answer and weaning a towel accross my face only present's something else to catch fire.I kjnow, if things get stinky and ugly, I'm not exactly breathing the fumes in deeply. More like hold your breath, do a bit and get to fresh air. Extinguish Jacket and Repeat.

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 7,047

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

Didn't take long to realize welding nude isn't the answer and weaning a towel accross my face only present's something else to catch fire.

No pics necessary. Thanks.

user.69169

Veteran Member

- Joined

- Feb 22, 2009

- Messages

- 1,346

You gonna run bandsaw learn about waxing blade.

Like dis man says, even a candle works, you don't need fancy bandsaw wax.

Wax Your Blades [Pro Tip Series #8] - YouTube

Like dis man says, even a candle works, you don't need fancy bandsaw wax.

Wax Your Blades [Pro Tip Series #8] - YouTube

jaxs

Elite Member

So you get the picture without actually seeing a picture? :cheerful:No pics necessary. Thanks.

Sberry

Platinum Member

Sberry

Platinum Member

Something to consider. There is a fascination especially on the internet with 45s and tuning too. With most of this work its design and build and I really rarely buy much steel. I find it, salvage and if it can be built from bent or angle it's used.

One of the benefits of being the designer is to build easy and I ain't got to use every angle they ever invented and most of what I see it on newbie projects it doesn't add anything due to the basics of joint and brace design not always understood.

When I was slumming I was a smart jazz, I was a new hire and the guy want me to build a bench and was really surprised when I had it working shortly after lunch. Last one they build take a week or 10 days.

I see one on the net recent described as "simple" bench, had 75 pieces with 20 diag cuts fits welds grind down could have do mb e and looked the same for 13 straight cuts on a chop saw with a bent wheel.

Nice enough bench but not simple and 2 weeks hard work. I did stuff more like a that when I started, took a while to become efficient fabricator.

One of the benefits of being the designer is to build easy and I ain't got to use every angle they ever invented and most of what I see it on newbie projects it doesn't add anything due to the basics of joint and brace design not always understood.

When I was slumming I was a smart jazz, I was a new hire and the guy want me to build a bench and was really surprised when I had it working shortly after lunch. Last one they build take a week or 10 days.

I see one on the net recent described as "simple" bench, had 75 pieces with 20 diag cuts fits welds grind down could have do mb e and looked the same for 13 straight cuts on a chop saw with a bent wheel.

Nice enough bench but not simple and 2 weeks hard work. I did stuff more like a that when I started, took a while to become efficient fabricator.

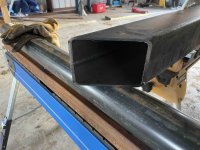

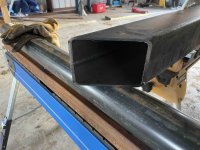

I took a one day class to at least get me going with stick welding. I feel like I need a one day on how to just stick things together efficiently. I am an overthinker, but am learning that it takes time to get all the stuff cut, ground, and welded so I need to be wiser when I need to do something or not. I guess you learn over time. I wish I had a buddy that was a guru that could just say "hey idiot, do it this way." The bandsaw worked great on the first project. My cuts are at least straight and more consistent. I realized I should have taken an easier way out on the corners, but wanted to practice trying to do 45's. They weren't necessary and my cheap internet find on steel was too large for the bandsaw, so I ended up using a grinder and cutoff more than I wanted. The band saw also made quick work of the repeated cuts and let me stack and get more material in between. I do see how a basic abrasive chop saw would make some of those cuts even faster.

Attachments

Sberry

Platinum Member

Thats quite a starter project.

Rebeldad1

Veteran Member

- Joined

- Sep 16, 2009

- Messages

- 1,603

- Location

- Hughett Bend Washington

- Tractor

- Kioti Tractor, John Deere Mower,New Holland Mini Excavator

never liked a chop saw or being around one. I have used a metal cutting bandsaw for lots of years. never had a issue. great for 90 degree and angle cuts. cuts are very accurate.

I have a old(er) version of this from central machinery. cuts up to 4X6"

www.harborfreight.com

www.harborfreight.com

paid for it on my first job. Built a lot of stuff since. great as well for cutting lots of small parts as well

I have a old(er) version of this from central machinery. cuts up to 4X6"

1 HP 4 in. x 6 in. Horizontal/Vertical Metal Cutting Band Saw

Amazing deals on this 4In X 6In ***/Vert Metal Cutting Band Saw at Harbor Freight. Quality tools & low prices.

paid for it on my first job. Built a lot of stuff since. great as well for cutting lots of small parts as well

MickeyDBC

Gold Member

I have a bit of a saw problem. I have a cold saw, couple of vertical bandsaws, 3 auto feed horizontal bandsaws (bought another one today - an Amada HA250W), a 10HP Kalamazoo chop saw, high speed non-ferrous saws, etc... But for fab work I have found my new best friend. I saw a review of the Diablo Steel Demon blades and figured I would give them a try on a project I am working on right now (an 800 gallon water wagon). They claimed that they would work on a regular miter saw and so I bought a pair of 12" ones to use on an old 12" PorterCable wood miter saw and these things are great. I have about a dozen cuts on 4x4x3/16" square tube and a dozen or so on 4x4x1/4" angle and no dulling evident yet. Blade was about $30 each and the cuts are great.

Last edited:

Here are some similar links:

- Replies

- 7

- Views

- 1K

- Replies

- 0

- Views

- 599