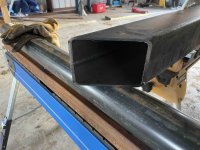

I took a one day class to at least get me going with stick welding. I feel like I need a one day on how to just stick things together efficiently. I am an overthinker, but am learning that it takes time to get all the stuff cut, ground, and welded so I need to be wiser when I need to do something or not. I guess you learn over time. I wish I had a buddy that was a guru that could just say "hey idiot, do it this way." The bandsaw worked great on the first project. My cuts are at least straight and more consistent. I realized I should have taken an easier way out on the corners, but wanted to practice trying to do 45's. They weren't necessary and my cheap internet find on steel was too large for the bandsaw, so I ended up using a grinder and cutoff more than I wanted. The band saw also made quick work of the repeated cuts and let me stack and get more material in between. I do see how a basic abrasive chop saw would make some of those cuts even faster.