dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,700

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

I'm still a little worried about the 3/4" pins given the forces involved.

You should be. Somewhere in this thread, I posted about this issue when I talked

about converting from mechanical to hydraulic.

On a couple of my mechanical thumbs, I bent the 3/4" pins I used. Of course, my

Deeres and Kiotis ran at 2500psi, while my Kubs were down at 2000. I think your

B is also limited to 2000psi. Check that. 1" pins should be used, IMO.

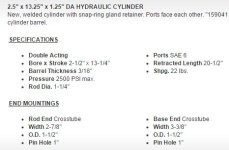

To belabor another point I made, converting an existing mechanical thumb will

force you into getting exactly the correct hydraulic cylinder stroke and length. This

is cuz your pivot point on the thumb is already fixed. I suggest you use mockups

of your cylinder to get the length and stroke just right. Even a 1/2" off and your

rest position against the dipper will be sub-optimal.