You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Driving a well point?

- Thread starter zmoz

- Start date

- Views: 78381

More options

Who Replied?

/ Driving a well point?

#21

foggy1111

Elite Member

We have LOTS of sand point wells in my area. The water table is eveident by the swamps and lakes scattered throughout the area. The entire area is sand, sand, sand, sand.....well you get my point.

By definition: the difference between a "shallow" and "deep" wells is that a shallow well is 25 feet or less. A deep well is over 25 feet and will need some other type of pump than vacuum to operate.

I plan to drive a sand point later this summer. If you have electricity available then many folks around here use an electric jack hammer (from the rental store) to drive the well pipe. That is my plan as they rent those for about $50 and save allot of work.

Also I recently had read where (in sand) a fellah used a shop vac with a rigid hose to vacuum his starter hole about six feet deep. I hauled my shop vac out to my property to give it a try....but have not gotten that far yet. I can see it working....but otherwise will use a hand post digger to drill a 6" starter hole.

Good luck.....you can read LOTS about wells on the web.

By definition: the difference between a "shallow" and "deep" wells is that a shallow well is 25 feet or less. A deep well is over 25 feet and will need some other type of pump than vacuum to operate.

I plan to drive a sand point later this summer. If you have electricity available then many folks around here use an electric jack hammer (from the rental store) to drive the well pipe. That is my plan as they rent those for about $50 and save allot of work.

Also I recently had read where (in sand) a fellah used a shop vac with a rigid hose to vacuum his starter hole about six feet deep. I hauled my shop vac out to my property to give it a try....but have not gotten that far yet. I can see it working....but otherwise will use a hand post digger to drill a 6" starter hole.

Good luck.....you can read LOTS about wells on the web.

ToadHill

Elite Member

- Joined

- Oct 18, 2005

- Messages

- 2,722

- Location

- Catt county New York

- Tractor

- Kioti DK35, Ford 8N, Oliver Cletrac

The double meter worked for me. When I ran my business I was filling a 100 gallon tank several times a day and the double meter saved me untold $$ on my sewer bill.

The only problem I had was when I installed it I had the inspector come out to approve the installation. He looked at it and said I'd have to do it over again since I couldn't use plastic pipe. When I asked why he said "If you have a fire the pipe could melt" I said if the fire melts the pipe isn't that a good thing, it just may put the fire out. He didn't like my answer, so I replumbed it with copper.

The only problem I had was when I installed it I had the inspector come out to approve the installation. He looked at it and said I'd have to do it over again since I couldn't use plastic pipe. When I asked why he said "If you have a fire the pipe could melt" I said if the fire melts the pipe isn't that a good thing, it just may put the fire out. He didn't like my answer, so I replumbed it with copper.

Tim Stuart

Silver Member

- Joined

- Jun 5, 2007

- Messages

- 125

- Location

- Coldspring, TX

- Tractor

- Mitsubishi bd2h dozer, Gradall G3WD, New Holland TC35a, Chevy Dump Truck

I have a started one myself, The wife wants a hand pitcher pump in the yard, She is going to build a flower bed around it. I figured if I was going to have to buy it ( for looks) I might as well try to make it work. So I work on it in my spare time. I am down about 16 feet so far. I used 3/4 pvc pipe with a jet nozzle on it hooked to a water hose. The jet nozzle cost about 2 bucks at Lowes. You just turn the water on and hold the nozzle to the ground and start washing a hole in the ground working the pipe in a up and down motion. You will be surprised how fast it will go down. I am washing a hole big enough for a 2 inch pvc pipe casing. I probably only have 2 hours in on it so far and my land is hard clay but has a springs oozing from the ground on the hills in places.

Attachments

jenkinsph

Super Star Member

As Tim suggest jetting may be a good way to go and combine this with a pressure washer and 3/8" sch 80 pipe for the nozzle and add sections of pvc casing washing them both down until you get where you wan't to be.

Will need to alternate between the pressure washer and a hose with enough flow to carry the solids out of the hole though.

Will need to alternate between the pressure washer and a hose with enough flow to carry the solids out of the hole though.

I was just thinking about a pressure washer when I read Tim's post. Seems like that might work well in clay soil. I've got lots and flow and pressure from my city water supply for digging. (and I **** well better for the price!)

(this is why I'm not asking the city any questions about my possible well )

)

You mean rigid copper with soldered joints? What happens to them in a fire?He looked at it and said I'd have to do it over again since I couldn't use plastic pipe. When I asked why he said "If you have a fire the pipe could melt" I said if the fire melts the pipe isn't that a good thing, it just may put the fire out. He didn't like my answer, so I replumbed it with copper.

(this is why I'm not asking the city any questions about my possible well

J

JCB

Guest

zmoz,

If you've never tried to unsweat a copper pipe filled with water, let me save you the trouble...it doesn't work.

Even a little water in the pipe will carry away too much heat for a propane torch to unsweat (solder), an acetylene or mapp torch gives you a better chance but still isn't enough heat.

Good luck with your well, and do yourself a favor and do a water test so you know whether or not its safe to take a mouthful while you're watering your plants.

If you've never tried to unsweat a copper pipe filled with water, let me save you the trouble...it doesn't work.

Even a little water in the pipe will carry away too much heat for a propane torch to unsweat (solder), an acetylene or mapp torch gives you a better chance but still isn't enough heat.

Good luck with your well, and do yourself a favor and do a water test so you know whether or not its safe to take a mouthful while you're watering your plants.

Tim Stuart

Silver Member

- Joined

- Jun 5, 2007

- Messages

- 125

- Location

- Coldspring, TX

- Tractor

- Mitsubishi bd2h dozer, Gradall G3WD, New Holland TC35a, Chevy Dump Truck

Guys, Keep in mind I am doing mine with just city water pressure connected to a 3/4 pvc pipe. I acualy did the first hole 5 to 7 feet with just the jet nozzle on the water hose but could not keep it going straight so I pulled it out and started over with the PVC pipe moving it over a foot. That being said I have already done 20 feet. It works very well with just the jet nozzle , pvc pipe and city water pressue.

Bill Barrett

Platinum Member

- Joined

- Jul 11, 2006

- Messages

- 671

- Location

- midwest

- Tractor

- Kubota L3130, Satoh G650, Case 580, Case 446

Guys, Keep in mind I am doing mine with just city water pressure connected to a 3/4 pvc pipe. I acualy did the first hole 5 to 7 feet with just the jet nozzle on the water hose but could not keep it going straight so I pulled it out and started over with the PVC pipe moving it over a foot. That being said I have already done 20 feet. It works very well with just the jet nozzle , pvc pipe and city water pressue.

I've jetted wells for years, the only way to go!

I use a 2" trash pump hooked to large water tank.

Trash pump to a 5' piece of 2" galvinized pipe with the end shapened.

Add pipe as needed.

Also you can see what material you're going through.

Layer of sand and gravel on top of clay is the best.

When you are where you want, drop an 1 1/4" PVC with PVC point down the center.

Pull the 2" up from around the PVC.

After the set up usually take about 5 minutes to jet a well 20'.

If your clay is at 18' or so your ok.

If you're clay all the way down with layers of sand at different levels it will be a pain.

Illini22

Gold Member

- Joined

- Aug 14, 2007

- Messages

- 472

- Location

- Northern Illinois

- Tractor

- 2013 Kioti dk40 hst, wright stander zero turn

Go on utube and search well drilling. They show different ways to jet a well.

I'm really liking this jetting idea. I've been looking for an excuse to buy a trash pump...I've jetted wells for years, the only way to go!

I use a 2" trash pump hooked to large water tank.

I was only talking about if there was a fire...where plastic water pipes could melt...I'm just guessing most of the copper joints would burst if your house was burning, although that seems like a good thing to me.If you've never tried to unsweat a copper pipe filled with water, let me save you the trouble...it doesn't work.

I will have the water tested if I find it...and if it's clean, I'll probably drink it in preference to our fancy tap water. It's pumped from one of the most polluted rivers in the country, downstream from at least 2 sewage discharges and an old leaching landfill...*sigh*

crazyal

Super Member

I never realized there was a name for it but I once installed a well using a pressure washer. It was a little messy but is sure beat trying to drive a pipe by hand. I did the first few feet with a hose and then turned to the PW with the pressure turned down.

chasbear

New member

- Joined

- May 17, 2010

- Messages

- 5

- Tractor

- One VERY Poorly 1975 IH 784

You could build yourself a well drilling outfit that can go down 300 feet or so. My Grandfather and Father drilled wells with one many years ago. Took about four days or so.

What kind of pump can you use with a well that's drilled to this kind of depth? I would assume that something of this depth needs a small type of mechanical lifting arrangement rather than an electrical pump? For that matter, a well driven with a point beyond a certain point, simply because of the diameter of the pipe used, also cannot accommodate a submersible pump and jet pumps don't work either?

Our place once had a hand-dug well to 90 feet with 10 feet of standing water in it. Tragically, a baby fell into it some years back and it was then covered and is now used as a cesspool. But we still have water supply problems here so I'm also researching what route to go.

Brad_Blazer

Veteran Member

What kind of pump can you use with a well that's drilled to this kind of depth? I would assume that something of this depth needs a small type of mechanical lifting arrangement rather than an electrical pump? For that matter, a well driven with a point beyond a certain point, simply because of the diameter of the pipe used, also cannot accommodate a submersible pump and jet pumps don't work either?

Our place once had a hand-dug well to 90 feet with 10 feet of standing water in it. Tragically, a baby fell into it some years back and it was then covered and is now used as a cesspool. But we still have water supply problems here so I'm also researching what route to go.

Submersible well pump.

Amazon.com: submersible well US Home Improvement

The old well - I wouldn't be too keen on on putting sewage deep in the aquifer. Think about reclaiming it for irrigation. A submersible pump still allows the use of a solid cap.

Egon

Epic Contributor

[What kind of pump can you use with a well that's drilled to this kind of depth?/QUOTE]

These wells were usually cased with 6 inch pipe. At that time most used a sucker rod PD pump but when the hydro came they would add a pumpjack and electric motor instead of the windmill or gasoline engine. Lots worked on hand power too.

Then they installed the downhole centrifugals or jet pumps.:thumbsup:

chasbear

New member

- Joined

- May 17, 2010

- Messages

- 5

- Tractor

- One VERY Poorly 1975 IH 784

Submersible well pump.

Amazon.com: submersible well US Home Improvement

The old well - I wouldn't be too keen on on putting sewage deep in the aquifer. Think about reclaiming it for irrigation. A submersible pump still allows the use of a solid cap.

I should have been clearer about my question, since I was assuming Egon was talking about sinking a well with a small diameter pipe, which he kindly cleared up for me with his post. Your link, Brad, shows a submersible pump with a 4" diameter, easily fitting into typical "big-rig" drilled well with a typical 6" casing.

Fortunately, the old well doesn't take on any sewage, but acts more like a dry well for draining the excess rain runoff from the yard.

[What kind of pump can you use with a well that's drilled to this kind of depth?/QUOTE]

These wells were usually cased with 6 inch pipe. At that time most used a sucker rod PD pump but when the hydro came they would add a pumpjack and electric motor instead of the windmill or gasoline engine. Lots worked on hand power too.

Then they installed the downhole centrifugals or jet pumps.:thumbsup:

So here's what I'm really interested in learning, and hadn't clearly seen yet in all of my "googling;" is it possible to go down, say, 100 feet with one of the simpler methods described here on this thread AND end up with a casing large enough for a submersible pump? For most of what I've seen for a do-it-yourselfer like me, I have assumed (and we all can now see how well that's worked out for me, eh?) is that I'd end up with a smaller diameter casing/pipe that precluded an electricity driven submersible pump. Actually, I say do-it-yourself pretty casually; I'll most likely have a few of my regular laborers (well-paid at the equivalent of $2.50/day) doing all of the heavy, labor-intensive work, but still avoid a costly drill rig I hope!

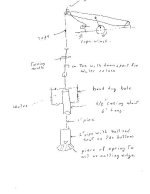

Egon, your method seems to me to be the only one that can give a casing large enough for a submersible pump at the depth needed for situations like mine, then. All I gotta do is study that sketch you posted a leeetle bit harder... any chances you could enhance it some? Thanks.

Bill Barrett

Platinum Member

- Joined

- Jul 11, 2006

- Messages

- 671

- Location

- midwest

- Tractor

- Kubota L3130, Satoh G650, Case 580, Case 446

I should have been clearer about my question, since I was assuming Egon was talking about sinking a well with a small diameter pipe, which he kindly cleared up for me with his post. Your link, Brad, shows a submersible pump with a 4" diameter, easily fitting into typical "big-rig" drilled well with a typical 6" casing.

Fortunately, the old well doesn't take on any sewage, but acts more like a dry well for draining the excess rain runoff from the yard.

So here's what I'm really interested in learning, and hadn't clearly seen yet in all of my "googling;" is it possible to go down, say, 100 feet with one of the simpler methods described here on this thread AND end up with a casing large enough for a submersible pump? For most of what I've seen for a do-it-yourselfer like me, I have assumed (and we all can now see how well that's worked out for me, eh?) is that I'd end up with a smaller diameter casing/pipe that precluded an electricity driven submersible pump. Actually, I say do-it-yourself pretty casually; I'll most likely have a few of my regular laborers (well-paid at the equivalent of $2.50/day) doing all of the heavy, labor-intensive work, but still avoid a costly drill rig I hope!

Egon, your method seems to me to be the only one that can give a casing large enough for a submersible pump at the depth needed for situations like mine, then. All I gotta do is study that sketch you posted a leeetle bit harder... any chances you could enhance it some? Thanks.

A packer assembly will use the outside pipe and a drop pipe in the center to a packing assembly. Works like a two pipe jet system.

Illegal in some if not most states.

chasbear

New member

- Joined

- May 17, 2010

- Messages

- 5

- Tractor

- One VERY Poorly 1975 IH 784

A packer assembly will use the outside pipe and a drop pipe in the center to a packing assembly. Works like a two pipe jet system.

Illegal in some if not most states.

Thanks Bill Barrett! Your information about a packer assembly opens up a whole new avenue of thinking about this for me. I found an excellent page HERE from Gould Pumps that shows the packer assembly used with either a 2" or 3" casing, the 2" of course being the more do-able solution. So now my next challenge is to find out what's available here in my area (Republic of the Philippines) for this type of assembly.

bp fick

Super Member

This thread got me psyched to get my own irrigation well put in. We've had a severe drought for a year, so I have to get it in gear.

Picked up a shallow well 1/2 hp pump and 10 gallon tank for $90. off Craigs today. I'll work on the drive point, pipe, drive couplings, etc this week.

Picked up a shallow well 1/2 hp pump and 10 gallon tank for $90. off Craigs today. I'll work on the drive point, pipe, drive couplings, etc this week.

What do you guys think about using a pressure washer nozzle like this:

Jetter/Drain Cleaning Stainless Steel Sewer Jetting Nozzles 17.0825 17.0827 17.0828 17.0829 17.0842

It's designed to clean sewer lines. If I used a 2" PVC casing, and ran one of those down a hose in the center, can I expect to push the PVC in easily? (until I hit a rock...)

The last time I used my pressure washer it was to move a dump truck of gravel from here to there. I used the 0 degree nozzle and just blasted it all where I wanted it! I was amazed at what a good "excavation" tool it made.

Jetter/Drain Cleaning Stainless Steel Sewer Jetting Nozzles 17.0825 17.0827 17.0828 17.0829 17.0842

It's designed to clean sewer lines. If I used a 2" PVC casing, and ran one of those down a hose in the center, can I expect to push the PVC in easily? (until I hit a rock...)

The last time I used my pressure washer it was to move a dump truck of gravel from here to there. I used the 0 degree nozzle and just blasted it all where I wanted it! I was amazed at what a good "excavation" tool it made.

Here are some similar links:

- Replies

- 15

- Views

- 3K