s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,607

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

So in the process of planning out a generator install, I have run into an interesting (to me) twist in the National Electric Code (NEC), where wires are rated at one amperage for service entrance use and another amperage for feeder use.

As an example, #2 aluminum is rated for 90 amps as a feeder wire. Scenarios would be wiring from a main panel to a sub panel elsewhere in a home or for a barn, shed, etc. You would need a 90 amp breaker to protect the feeder wire according to code.

That same #2AL is rated for 100 amps as a service entrance wire. Scenarios would be running from power hookup or meter to main panel, or generator to main panel. In that case, you can use a 100 amp breaker to protect the service wire according to code.

Can anyone explain why this might be the case? I'm a mechanical engineer and have researched this up and down, and best I can tell is that it's just the way code is. But I'd really like to know why.

There are temperature ratings for the same wire gauge that show 75 amps for 60C rating, 90 amps for 75C rating, and 100 amps for 90C rating. I am not sure if this is related or not. #2AL I have seen is all rated to 90C, but most home circuit panel and breaker contacts/terminals are only rated for 75C.

(Note: I've use AL for the wire examples, but the same issue applies to copper -- it is rated to higher amperage for service entrance than feeder. The closest example is #4 copper.)

In our new home, we had #2AL run from the original proposed generator location to the main panel, and it is connected with a 100 amp breaker to backfeed into the panel (an interlock prevents that from being turned on unless the main has been shut off, and vice versa). It passed inspection just fine.

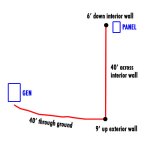

Because I am putting the generator farther from the house than planned, I am upsizing part of the feeder wire to #1/0 AL to minimize voltage drop, but plan to tie back into the #2 before it goes into the panel. I am debating whether or not I should pull the #1/0 all the way to the panel, which would be more work and more hassle. That's when I stumbled on this twist in the code for the rating of #2, and it got me wondering...

thanks,

219

As an example, #2 aluminum is rated for 90 amps as a feeder wire. Scenarios would be wiring from a main panel to a sub panel elsewhere in a home or for a barn, shed, etc. You would need a 90 amp breaker to protect the feeder wire according to code.

That same #2AL is rated for 100 amps as a service entrance wire. Scenarios would be running from power hookup or meter to main panel, or generator to main panel. In that case, you can use a 100 amp breaker to protect the service wire according to code.

Can anyone explain why this might be the case? I'm a mechanical engineer and have researched this up and down, and best I can tell is that it's just the way code is. But I'd really like to know why.

There are temperature ratings for the same wire gauge that show 75 amps for 60C rating, 90 amps for 75C rating, and 100 amps for 90C rating. I am not sure if this is related or not. #2AL I have seen is all rated to 90C, but most home circuit panel and breaker contacts/terminals are only rated for 75C.

(Note: I've use AL for the wire examples, but the same issue applies to copper -- it is rated to higher amperage for service entrance than feeder. The closest example is #4 copper.)

In our new home, we had #2AL run from the original proposed generator location to the main panel, and it is connected with a 100 amp breaker to backfeed into the panel (an interlock prevents that from being turned on unless the main has been shut off, and vice versa). It passed inspection just fine.

Because I am putting the generator farther from the house than planned, I am upsizing part of the feeder wire to #1/0 AL to minimize voltage drop, but plan to tie back into the #2 before it goes into the panel. I am debating whether or not I should pull the #1/0 all the way to the panel, which would be more work and more hassle. That's when I stumbled on this twist in the code for the rating of #2, and it got me wondering...

thanks,

219