mmranch

Gold Member

Thanks again to all for the ideas on this!

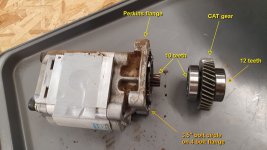

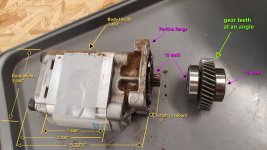

OK, I received the new drive gear from CAT and it is the correct gear (even if the parts technical drawings were incorrect). It has the proper 39 helical teeth and the side holes have the proper 10 teeth and 12 teeth. (I also ordered 2 of the new gears).

Now I am waiting on the new gear pumps from TYM. One was in-stock and the other was backordered. No info on when I might receive these pumps.

I mated both old pump's splined shafts with the new drive gear and even though the splined shaft on the main pump is very, very worn... the spline shafts are turned by the gear without slippage.

Since I don't know when the new gear pumps will arrive... I am considering rebuilding the tractor with the new gear and old pumps to try to get it working for the summer. The splines or gear may give out after a week, a month or a year... who knows?

Wish there was some glue I could squirt on the splines to fill voids and bind the splines into the gear hole better. Thought about welding on top of each spline to raise the worn spline areas then grinding out the grooves again. But the splines are small so it might not be possible. Thought about wedging some metal into the hole with the splines for a tighter fit. Thought about drilling a hole through the gear and splined shaft and using a roll pin to lock the shaft and gear together... not sure if the gear bearing can be pressed on to the gear with the shaft fixed to the gear.

May just have to rebuild and hope for the best!

Thanks again.

OK, I received the new drive gear from CAT and it is the correct gear (even if the parts technical drawings were incorrect). It has the proper 39 helical teeth and the side holes have the proper 10 teeth and 12 teeth. (I also ordered 2 of the new gears).

Now I am waiting on the new gear pumps from TYM. One was in-stock and the other was backordered. No info on when I might receive these pumps.

I mated both old pump's splined shafts with the new drive gear and even though the splined shaft on the main pump is very, very worn... the spline shafts are turned by the gear without slippage.

Since I don't know when the new gear pumps will arrive... I am considering rebuilding the tractor with the new gear and old pumps to try to get it working for the summer. The splines or gear may give out after a week, a month or a year... who knows?

Wish there was some glue I could squirt on the splines to fill voids and bind the splines into the gear hole better. Thought about welding on top of each spline to raise the worn spline areas then grinding out the grooves again. But the splines are small so it might not be possible. Thought about wedging some metal into the hole with the splines for a tighter fit. Thought about drilling a hole through the gear and splined shaft and using a roll pin to lock the shaft and gear together... not sure if the gear bearing can be pressed on to the gear with the shaft fixed to the gear.

May just have to rebuild and hope for the best!

Thanks again.