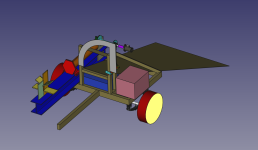

I agree that everyone has different needs so if you are building your own equipment, no matter what it is, build it to the specs of what YOU need it to do, not what others need it to do. In my opinion, if you are looking for a processor that doesnt need any other equipment like tractors with forks or grapples to load the wood onto the processor, the second design that Polmidis has shown would be the best option. But having said that you will have to get the logs out of the bush to the processor. This is the reason I am building one of that design, even though I do have a tractor with forks and grapple. It just saves me one more step I the whole process. Park the processor at one end of the log pile and pull off the pile with the winch. Sounds easy to me.

Correct me if im wrong but isnt the W beam that you are talking about, a wide flange I beam with a heavier flange and web. I just never heard them called a W beam before.

The 12 second cycle time is with a four inch cylinder. Around here most of the firewood is either jack pine, spruce, or poplar and in the past 17 years of cutting firewood I have seldom had a tree over 16 inches so a four inch cylinder will work good for me and the trees I have around here.