jcrotts110

New member

- Joined

- Jun 4, 2021

- Messages

- 7

- Tractor

- 1952 Ford 8n

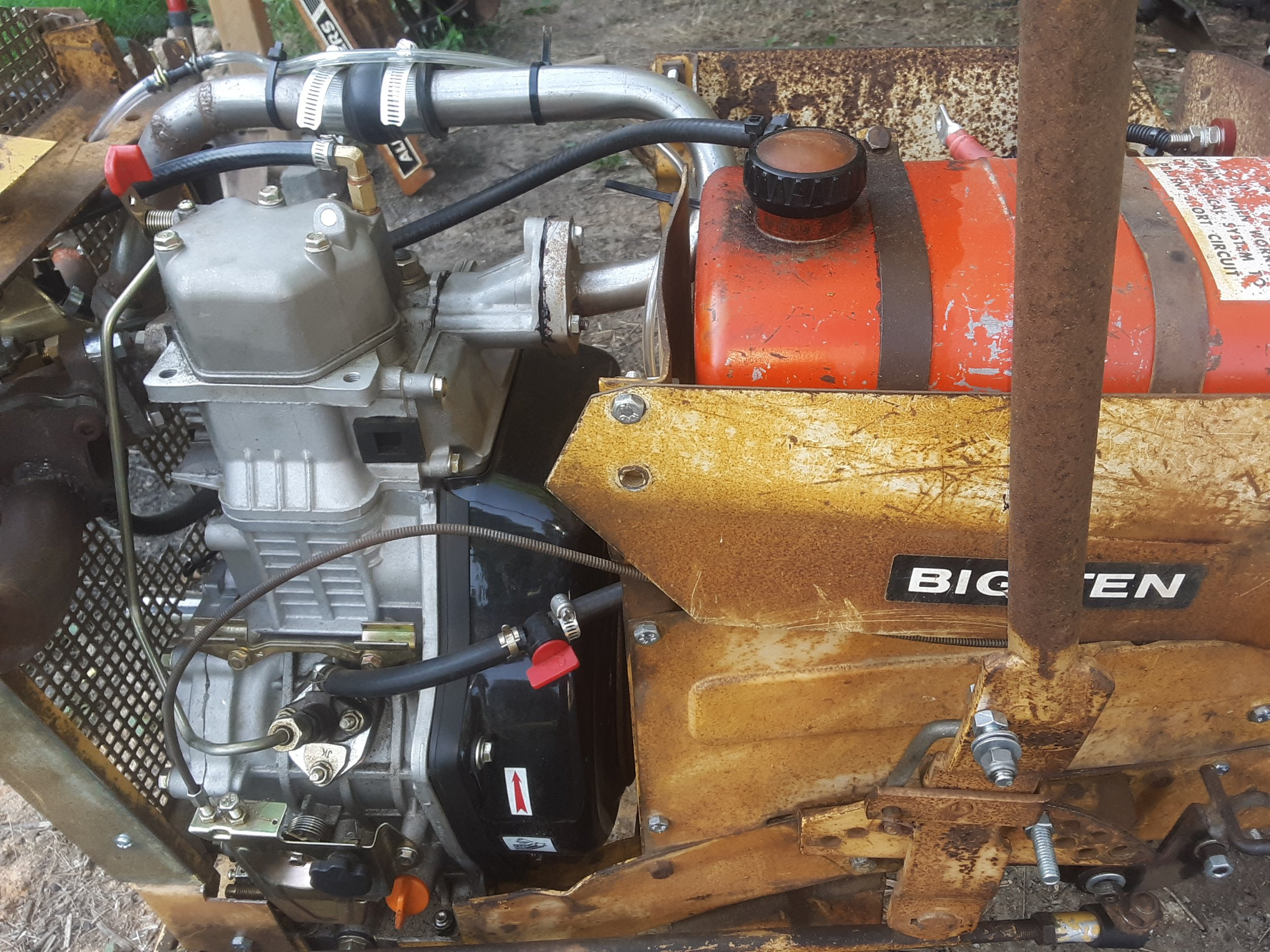

Here are the photos.

The old engine was beyond finished. You could move the crank all over the place. The bearings were worn out You probably wouldn't notice anything was "off" at first glance if the turbo wasnt hanging out the front. I had to BUTCHER the front end to get everyting to fit the frame without removing too much material, but that was the hardest part. The only issue is that I have to pull the engine to get to the oil filter.

To mount the drive shaft I made an adapter out of 1/2" steel plate, since the holes where the starter cup goes are all off center. Its attached to the center of the flywheel with counter sunk metric grade 12.9 8mm bolts and thread locker. Everything else bolts to the adapter.

I tried to use the starter/generator for a while, but I could never get it aligned right and it would eat the belt. Every time I wanted to use it I would have to tighten the belt, and that got annoying very quickly. It's not hard to pull start. Just use the compression release and the gearbox starter, follow through with the pull, and it fires right up.

I might tear it down to make a few things on the engine look better and for some bodywork and paint this fall when I don't need it to mow anymore.

The old engine was beyond finished. You could move the crank all over the place. The bearings were worn out You probably wouldn't notice anything was "off" at first glance if the turbo wasnt hanging out the front. I had to BUTCHER the front end to get everyting to fit the frame without removing too much material, but that was the hardest part. The only issue is that I have to pull the engine to get to the oil filter.

To mount the drive shaft I made an adapter out of 1/2" steel plate, since the holes where the starter cup goes are all off center. Its attached to the center of the flywheel with counter sunk metric grade 12.9 8mm bolts and thread locker. Everything else bolts to the adapter.

I tried to use the starter/generator for a while, but I could never get it aligned right and it would eat the belt. Every time I wanted to use it I would have to tighten the belt, and that got annoying very quickly. It's not hard to pull start. Just use the compression release and the gearbox starter, follow through with the pull, and it fires right up.

I might tear it down to make a few things on the engine look better and for some bodywork and paint this fall when I don't need it to mow anymore.