My hat is off to him for taking his cylinders apart and having a look. Right or wrong, so far it is the only positive mechanical information that we have.

If not a solid stop, how about Hydraulic Shock? Given high RPM and a load in the bucket, could suddenly reversing the swing with the control levers create enough tensile force on that rod end to cause the failure?

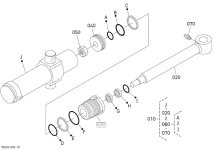

And looking at the cylinder rod, we have to wonder what mods to piston and rod would make sense to increase the strength of the threaded portion? I'm sure your co-worker put some thought into that. What conclusions?

A shock-damping damping reservoir on a T in the pressure feed line would be another solution.

I will be fascinated to hear what you find in yours.

rScotty

Yeah, right now we have a few examples in the experiment, but only 1 actual data point. I'll become the 2nd when I have time to dig in.

My coworker felt the heat treatment was wrong on the shaft. He also felt the machining on the shaft left stress concentration areas as they left sharp corners rather than had radii. Since the Kubota shaft failed, he didn't want to give Kubota the ~$450 they wanted for a new shaft. He went to a local shop that fabricates cylinders and they cut off the pin end of the shaft and welded it to a new shaft they fabricated.

Momentum and sudden stopping could be the cause. My coworker can be an animal on the controls from the stories I've heard. On the other hand, I'm generally gentle, but I do use my backhoe to move some pretty large logs around during firewood operations. Maybe I stopped the controls at some point and it let loose. We're really just theorizing until I can get in there.

I need to look at the physical hoses/fittings to see if I can easily just rig up one cylinder at a time.

ac