Here's some stuff that may help - (NOT specific to your Kubota)

hydraulic supermarket | technical library

More to the point -

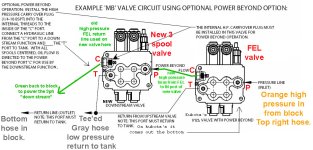

How to configure mobile hydraulic valves using power beyond

As already mentioned, most hydraulic valves, either stacked (modular) or monoblock (what you bought is what you got, period) do NOT like to see more than typically 500 psi in the Tank gallery - so when you're not actually using a valve, the flow from the pump just passes thru the valve galleries and back to tank.

The portion of the casting that has the tank port may(or may not) also have an OPTIONAL PB port - if that option is NOT installed, then the tank gallery and the PB gallery are all connected, and pressure in that section stays low and returns fluid back to the tank.

Without PB, the extra port (PB) is plugged with a standard pipe plug (usually) - In order to add PB to such a valve, you remove the standard pipe plug from the PB port and REPLACE it with a PB adapter - this is essentially a glorified THROUGH adapter - it has a hole clear through, and various output threads depending on the manufacturer/model -

The DIFFERENCE in this PB adapter, is it ALSO has a STEPPED outer body, with O-ring seals between the steps - when it is inserted into the PB port, the innermost O-ring BLOCKS the connection between Tank gallery (low pressure only, seals NOT designed for high pressure) and the PB gallery (made for high pressure) -

Here's the PB adapter for Prince Stack valves, showing the stepped outer sleeve and the O-rings that separate the two galleries

https://www.surpluscenter.com/Hydra...-BEYOND-SLEEVE-FOR-PRINCE-SV-VALVE-9SV-PB.axd

So NOW, with the PB adapter in place, if you don't move any levers in the valve body, flow ONLY goes thru the PB adapter and on to the next valve in line, and finally to tank. (still at high pressure, but ONLY if you're actuating a valve (to a toplink, for example) -

In a typical open center system, when you actuate ANY cylinder from ANY valve, flow is re-directed - either to the "A" or "B" WORK port - whichever port (A or B) is pressurized, the OTHER work port gets routed to the Tank gallery to relieve pressure on the other side of the cylinder's piston - otherwise, the cylinder can't move.

Without a PB adapter in a control valve, ALL the pump flow just goes IN the Pressure port and OUT the Tank port UNTIL you move a lever, and a gauge placed ANYWHERE in that path will only read as much pressure as would be caused by various restrictions in tubing, hoses, open valves, etc.

WITH a PB adapter installed, the TANK port only feeds back to tank when a spool on THAT valve is moved - otherwise, ALL fluid continues on thru the circuit thru the PB adapter.

Not sure I cleared up ALL your questions, but hopefully it's a start... Steve