dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,689

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

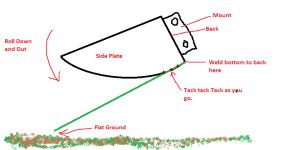

When I got to the point where I needed to bend the bottom of the bucket

I tacked the sides to my welding table so the front edge was flush with the edge of the table. Then I used

a ratchet strap to bend it around the sides. I would max out the strap make a few tacks and then reset the

strap.

Good pix, SFRANKLAND.

Your method is very similar to how I made my CADDigger bkt back in the 90s. Too bad all my

pix are from film and not easily locatable. The CADDigger is in my avatar.

Making the curved bkt was the most interesting part of my CADDigger build back then, cuz

I had never used this technique before. I followed the directions in the plans closely and first

welded up the sides of the bkt with the curve I wanted. Just as you did. The crazy thing is

that my bkt called for 1/4" plate, 13" wide! That's crazy-thick, and I do NOT recommend it.

I was able to bend-and-tack as you did, but I used a 2000# cable come-along and lots of

heat from a O/A torch, right at the bend line.

Now I know a better way: use only 1/8" plate, and add 1/4" or 3/16 wear strips afterwards.

MUCH easier to bend, and a lighter bkt.

A very rewarding build.