Harv

Elite Member

- Joined

- Aug 22, 2000

- Messages

- 3,371

- Tractor

- Kubota L2500DT Standard Transmission

Seems kinda late in the game for me to be asking this question, but it's mostly intellectual curiosity at this point. /w3tcompact/icons/clever.gif

In the <A target="_blank" HREF=http://www.tractorbynet.com/cgi-bin/compact/showflat.pl?Cat=&Board=buyjd&Number=99527&page=&view=&sb=&o=&vc=1>Trencher Attachment</A> thread, it's been stated that it's better to have HST for trenching operations 'cuz you need to go real slow. That got me to wondering a little more about the specifics of how HST does what it does.

From what I've read on this board in the last year or so, I've gathered that pushing down on the HST pedal is roughly equivalent to increasing the gear level that is driving the tractor. The farther you push it, the faster you go with less torque to the wheels. You let off and you slow down but increase your pulling power. Just like shifting to high gear and then back down to first on a manual transmission.

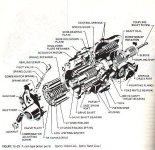

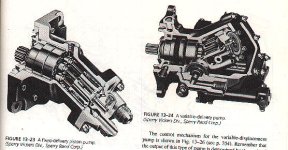

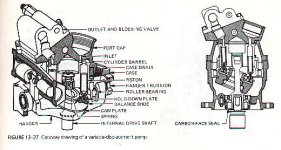

So my question is, what exactly is inside an HST box? If it indeed allows you to go slower (lower) than a manual low gear, does that imply that it is analog? Meaning there are no increments, but rather a true continuous range of operation? And if that is so, what is the actual mechanism?

Feel free to post pictures and diagrams. And maybe talk real slow...

In the <A target="_blank" HREF=http://www.tractorbynet.com/cgi-bin/compact/showflat.pl?Cat=&Board=buyjd&Number=99527&page=&view=&sb=&o=&vc=1>Trencher Attachment</A> thread, it's been stated that it's better to have HST for trenching operations 'cuz you need to go real slow. That got me to wondering a little more about the specifics of how HST does what it does.

From what I've read on this board in the last year or so, I've gathered that pushing down on the HST pedal is roughly equivalent to increasing the gear level that is driving the tractor. The farther you push it, the faster you go with less torque to the wheels. You let off and you slow down but increase your pulling power. Just like shifting to high gear and then back down to first on a manual transmission.

So my question is, what exactly is inside an HST box? If it indeed allows you to go slower (lower) than a manual low gear, does that imply that it is analog? Meaning there are no increments, but rather a true continuous range of operation? And if that is so, what is the actual mechanism?

Feel free to post pictures and diagrams. And maybe talk real slow...