DFB

Elite Member

- Joined

- Dec 7, 2000

- Messages

- 2,928

- Location

- Southern VT, Southern ME

- Tractor

- John Deere 4100 HST /410 FEL, R4s

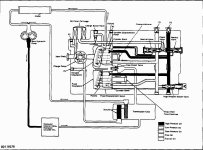

On the Deere there are directional control valves located in the valve block along with "valve plates" for both the pump and motor. Changing the position of the swash plate uncovers different slots in the valve plate.

In your drawing I would think those would be control valves. I see that your oil filter is located after the charge pump too.

DFB

In your drawing I would think those would be control valves. I see that your oil filter is located after the charge pump too.

DFB