Gotcha.

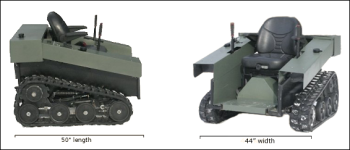

Keep in mind though that even 15 mph is going to be stretching it. In that Power Trac clip, they made it clear that they had no "attachments" available for it....such as a blade mount/three point/etc. Sounds (to me) like they made all the compromises they could in order for it to attain an "ATV-competitive" top speed, (and 14-16 mph isn't really competitive anyway), and sort of abandoned the notion that it's suitable for real work.

On another forum I frequent, one of the topics frequently discussed are issues with lawn and garden tractors. Breakdowns and lack of reliability are common discussions. The overwhelming majority of "issues" are experienced by the operators that are continuously asking too much of the machines. A good rule of thumb, is to consider what attachments the tractor manufacturer offers for a particular model. Lots of these guys buy a tractor and then build their own trailer, (that's too big), to pull around behind it, or they hook up to a large spike aerator, (and then add a bunch of weight to the tractor for traction), and try to drag it around. They can go right to the manufacturer's website or sales brochure and see that all that's listed for accessories for their model is a light-duty yard cart, and somehow that doesn't register.

In Power Trac's situation, I think the fact that they don't offer attachments is very telling. It certainly "looks like" it could be a real workhorse, but....

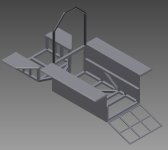

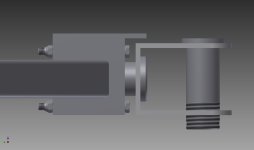

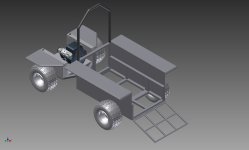

I definitely see your point, but I am looking at 10 to 15 hp more. Which should give me more torque at speeds of 15 mph, I also plan on having a high and low range. It's just a matter of figuring out which pumps and motors to accomplish what I want.