GuglioLS

Veteran Member

- Joined

- Feb 13, 2005

- Messages

- 1,155

- Location

- Edgewood, NM USA

- Tractor

- Jinma 354, 1953 Ford NAA Golden Jubilee, Komatsu Bulldozer

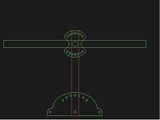

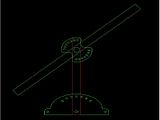

I've been wanting a landscape rake. I checked a few out in person, but none were configured exactly to my liking. So I have decided to build one from scratch.

Rob (3RRL) has been very generous and helpful in the design and build of my 360* rotating back-blade project and in designing the jaws and brackets for my grapple project For anyone who is following Rob's (3RRL) home build project right now Rob's plate is pretty full, so maybe I should give him a break and do this on my own? For the most part, many of my projects have been "built then designed" instead of being "Designed then built". For this Rake project, I have decided to Design then build. Last week I picked up AutoCad and are teaching myself how to use it with this project.

and are teaching myself how to use it with this project.

Here are the basic concepts of the rake I am going to build:

As you can see it will have a swivel offset and rotation angle feature. I will add index holes to pin the positions, but do plan on having it controlled by hydraulics. The design will be such that it could be manual or hydraulically operated.

Larry

Rob (3RRL) has been very generous and helpful in the design and build of my 360* rotating back-blade project and in designing the jaws and brackets for my grapple project For anyone who is following Rob's (3RRL) home build project right now Rob's plate is pretty full, so maybe I should give him a break and do this on my own? For the most part, many of my projects have been "built then designed" instead of being "Designed then built". For this Rake project, I have decided to Design then build. Last week I picked up AutoCad

Here are the basic concepts of the rake I am going to build:

As you can see it will have a swivel offset and rotation angle feature. I will add index holes to pin the positions, but do plan on having it controlled by hydraulics. The design will be such that it could be manual or hydraulically operated.

Larry